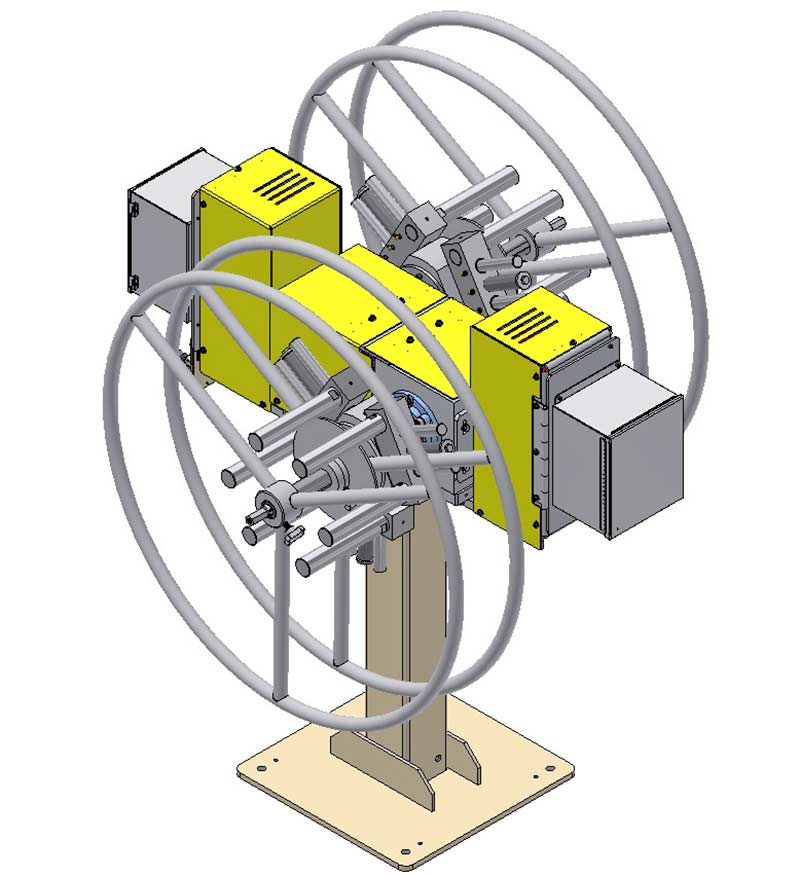

Machine Concepts’ Light Duty Decoilers offer a low cost solution to a wide range of light duty coil handling/payoff applications. This series of machines is designed to handle coil loads up to 2,500 pounds per mandrel. The light weight coils are clamped on the inner diameter using a hand ratchet system to expand and collapse on varying coil inner diameters. The use of the hand ratchet expand and collapse feature eliminates the cost and space consumption of a hydraulic system.

When paired with the Machine Concepts’ EV/L2 or G2 Precision Straighteners, these decoilers can achieve superior coil handling control. The electric motor powered payoff option allows these decoilers to feed extremely thin or low yield strength materials into a straightener without damaging the material. This feature prevents tension in the strip of material created between the straightener and decoiler when the straightener pulls material off of the coil. The electric motor powered payoff sustains a loop of material between the straightener and decoiler.

Standard Features

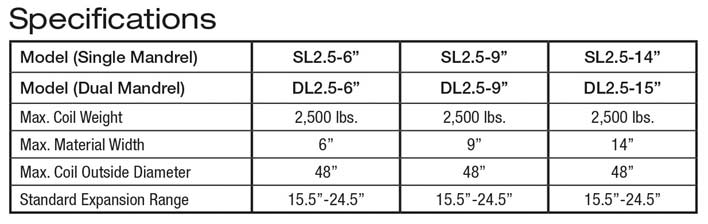

- Standard Sizes for 2,500 lb Coils

- Manual Crank, Gear Driven Mandrel Expansion – uses a wrench to turn the hex shaft which is connected to a set of internal gears. Each gear is connected to a threaded shaft that will adjust the expansions of the decoiler. The gears provide equal travel distance control for each of the three individual segments.

- Manual Mandrel Rotation with Coil – coil is pulled off by the straightener or by operator hand

- Adjustable Front and Back Coil Keepers

- Pneumatic Drag Brake – internal (inside bearing housing) or external (outside bearing housing)

- Manual Turret Rotation (Dual Mandrel Only) – operator rotates the mandrel turret using a handle and manual switch shot pin

- Pneumatic Shot Pin (Dual Mandrel Only) – controlled using an electric solenoid

- Fixed Base

Optional Features

- Motor Powered Payoff – uses an electric motor to payoff material from the coil at line speed and jog speed

- Proportional Drag Brake – helps maintain constant strip tensions as diameter of coil reduces

- Hold Down Arm – non-driven or driven hydraulic motor

- Wheel or Disc Style Keeper Arms – single wheel style keeper clamped to each mandrel. Requires operator to attach and clamp on segments after a coil is loaded.

- Coil Guard – guard mounted off the decoiler to contain coil clock-spring so strip does not hit personnel walking on back side

- Lower Base Traverse – self-centering manual or hydraulic adjustment

- Spool Decoiler – a single center shaft replaces the expansion system to allow the decoiler to run spools of material instead of bare coils. Using spools improves coil change time and are safer and easier to handle compared to bare coils.