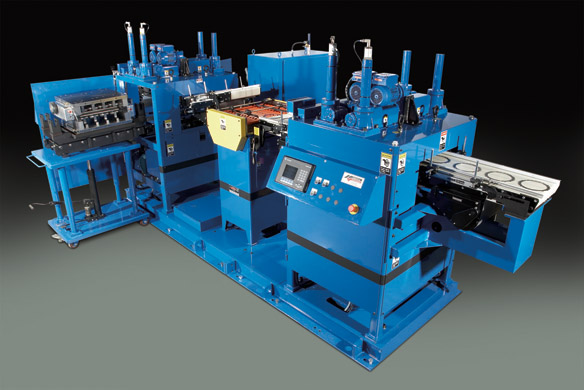

High-Performing Machines for Precision Parts Straightening

Achieving unsurpassed levels of flatness with proven performance and durability for today’s toughest materials.

Both the G2P and H2P series have been designed to obtain a level of flatness and speed that many other metal parts straighteners cannot achieve. Available in single and dual head configuration. Also available in single and double lane configuration.

Take the “Straightening Challenge”. Send us your poorest quality, toughest metal part and we’ll achieve a level of flatness that you’ve never imagined.

Applications: Clutch plates, saw blades, food processing knives, laser burnt parts, fine blank parts, etc.

Features

- Easy quick removal of roll cassette for cleaning or changing work rolls

- Multiple cassettes with different work roll diameters can be interchanged in the same basic machine

- Two-point belt drive connection system eliminates problems of U-joints and shortens installation time

- Hanging cassette design eliminates adjustment backlash and improves calibration reliability

- Precision ball and socket set to align top and bottom roll banks for accurate alignment

- Hardened and precision ground work rolls supported with double row needle bearings

- Continuous light oil lubrication with flow and level monitoring

- All electrical drives, controls and panels are machine mounted

- Proven performance and durability in the toughest stamping applications

Options

- Motorized entry and exit adjustment incorporates pushbutton control of entry and exit roll position with PLC controlled travel and tilt limits

- 4 hi, 5 hi, or 6 hi roll configurations available

- Double thickness protection to prevent two parts from entering cassettes stacked

- Entry feeder where an operator loads stacks of parts and the feeder/conveyor destacks one part at a time

- Automatic Parts Loader custom designed to application requirements

- Automatic Parts Re-stacking custom designed to application requirements

- Programmable job code storage of entry/exit settings and conveyor/cassette roll speeds based on part number

- Programmable speed control of all conveyors and cassette rolls

- Dual head straighteners with 90 degree parts rotation between heads

- Dual lane parts straightener can double production output (available in dual head configuration)