Let our robotic systems team solve your production, quality or ergonomic issues with an automated robotic solution.

At Machine Concepts, we specialize in designing and integrating custom robotic solutions to fit specific manufacturing needs. Our experienced team of engineers will evaluate your existing production process to uncover how to achieve the most from existing assets while integrating the latest automation technologies to move your operation to the next level.

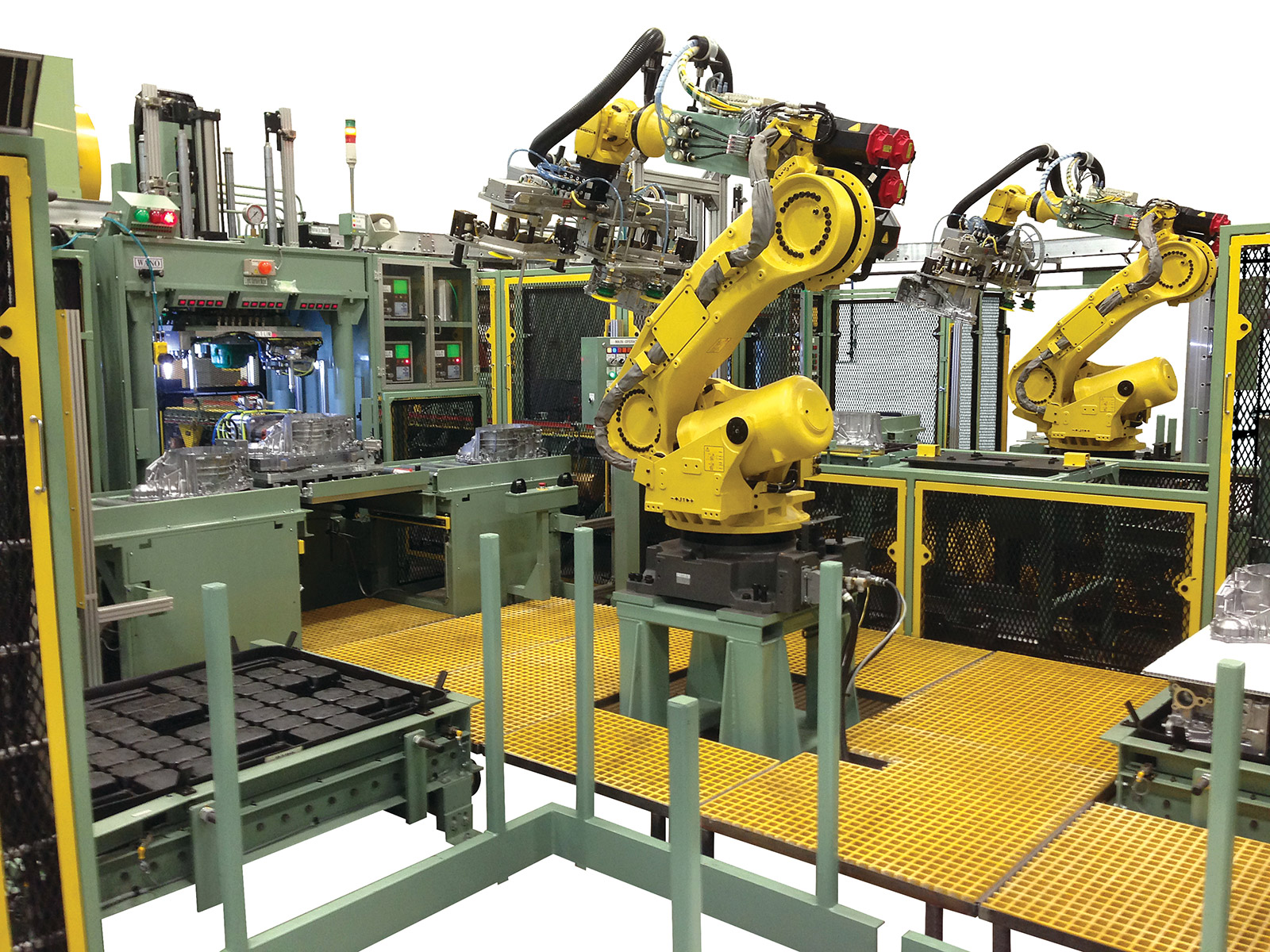

Robotic Inspection Cell

Robotic Systems Integration in Manufacturing

Robotic integration in manufacturing is the process of merging industrial robots into production lines to make production as efficient as possible. Industrial robots can provide improved quality and consistency, reduced cycle times, maximized throughput and reduced labor challenges, especially in manufacturing jobs that are difficult to fill.

How to Get Started with Robotic Integration

Start with a conceptional design and ROI study to discover the best robotic solution that will have the most impact on your productivity.

At Machine Concepts, our specialty is designing and engineering innovative solutions that increase productivity and quality, decrease production costs and improve operator safety. Our team of engineers, skilled machinists and project managers will partner with your team from concept to installation and operation

Machine Concepts Robotic Integrator Capabilities

- Turnkey Robotic Cells – Design to Startup

- Robotic Welding and Joining Systems

- Robotic Part Handling Systems

- Re-Tooling for Existing Cells

- Retrofit or Reprogramming of Existing Cells

- Design and Build End Effectors

- Integration with New and Existing Equipment

- Programming Changes and Modifications

- Model Changes with Modification or Redesign to the End Effector

Robotic Machine Tending Cell

Why Choose Machine Concepts as Your Robotic Integrator?

- Full staff of mechanical and electrical engineers and technicians

- Extensive experience integrating a wide range of processes including material handling, assembly and operations such as deburring or measuring

- Robot programmers also handle PLC and HMI programming to streamline integration

- Well-versed in Allen Bradley and Mitsubishi PLCs as well as experience with other manufacturers

- Experience with Fanuc IR Vision & Cognex Vision Systems

- CAD Software: Solidworks, Inventor and AutoCAD

- Programming Software: Fanuc Robot Simulation Software, Allen-Bradley, Mitsubishi, HMI screens

- Utilize software to simulate our customer’s robot cell, enabling us to pre-program a new robot or make modifications to an existing robot prior to installation, thus reducing production downtime to make the required changes