Scroll strip stamping is a creative way to scroll slitting lamination material of circular or hexagonal parts. During this process, a reduction of 12% to 29% can be achieved over straight slitting material. This process also controls the position of one part to another part very accurately that normal scroll slitting arbors cannot maintain. The end result is cost reduction of scrap for large motor lamination stampers.

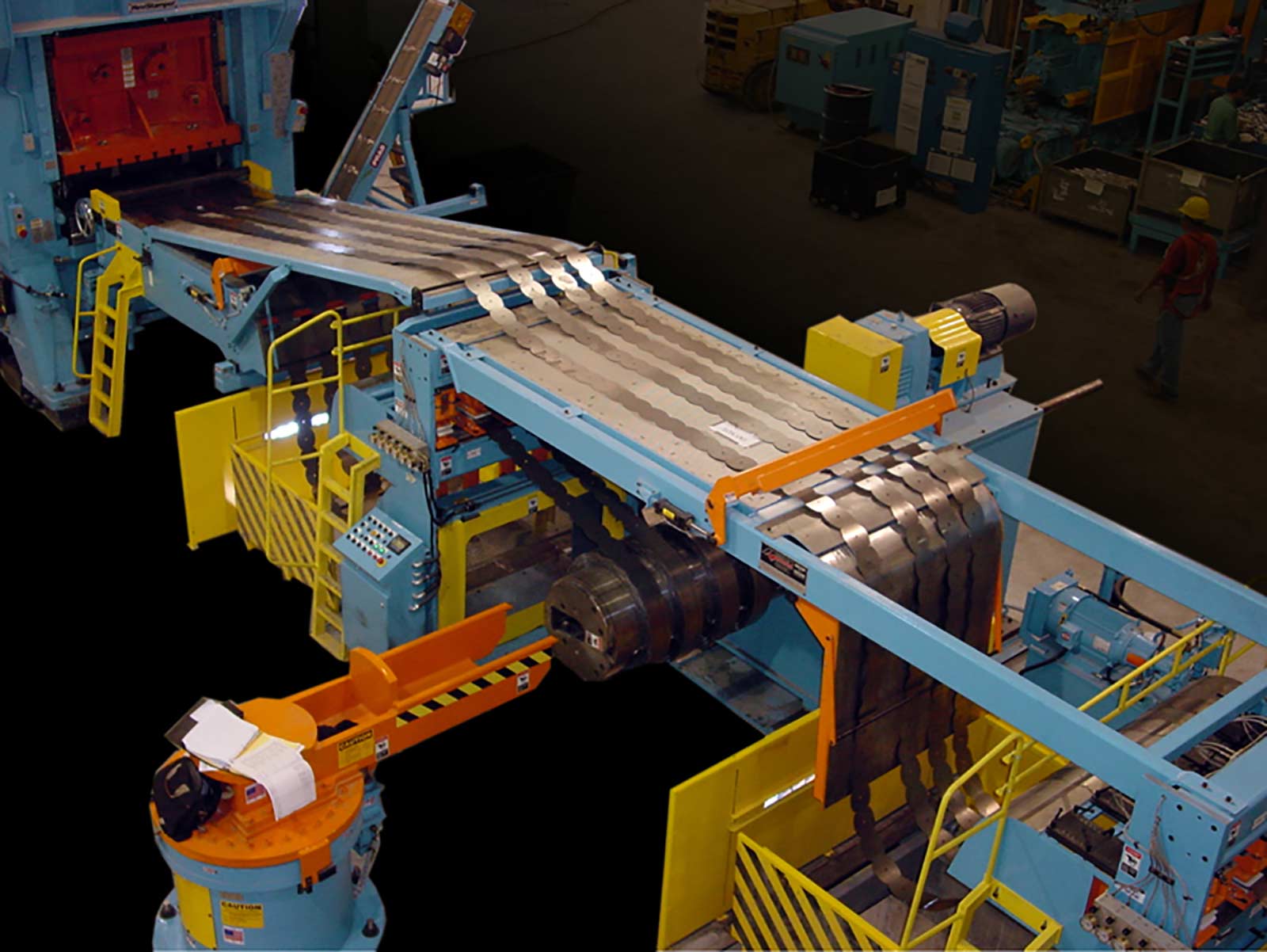

The process allows for material up to 50 inches wide to be uncoiled, straightened and fed into a stamping press to produce up to ten individual strips of scrolled material. These strips pass through a short looping pit and tension stand to be rewound back into coil form. The scrolled coils can be taken to secondary presses to complete the process of producing rotors and stators. The strips can be either single, double or triple width scroll strips based on the die construction.

Superior Tension Control & Loop Management

Machine Concepts has made several improvements to scroll processing over machines constructed in the past. One is the tension control and loop management of the strip coming out of the stamping press. Our design of tension stands has been tested against many other designs. It has been proven to control proper tension to maintain tight coils that do not slag under their own weight or telescope when rewinding into coils, while not over-tensioning the strips to cause the progression from part to part to be lost.

Increased Efficiency

In addition to the benefit of higher quality coils, Machine Concepts’ Scroll Slitting Lines are easy to set-up from one part number to another, very low maintenance and/or service cost, inexpensive wear components and reliable uptime. Combined with Machine Concepts’ Leveler, S-Loop and a strong lamination Feeder, these lines typically produce two to three times the output of our competitors.

Looping pits allow for strip thickness variances while enabling high run speeds and superior coil tension compared to competitors

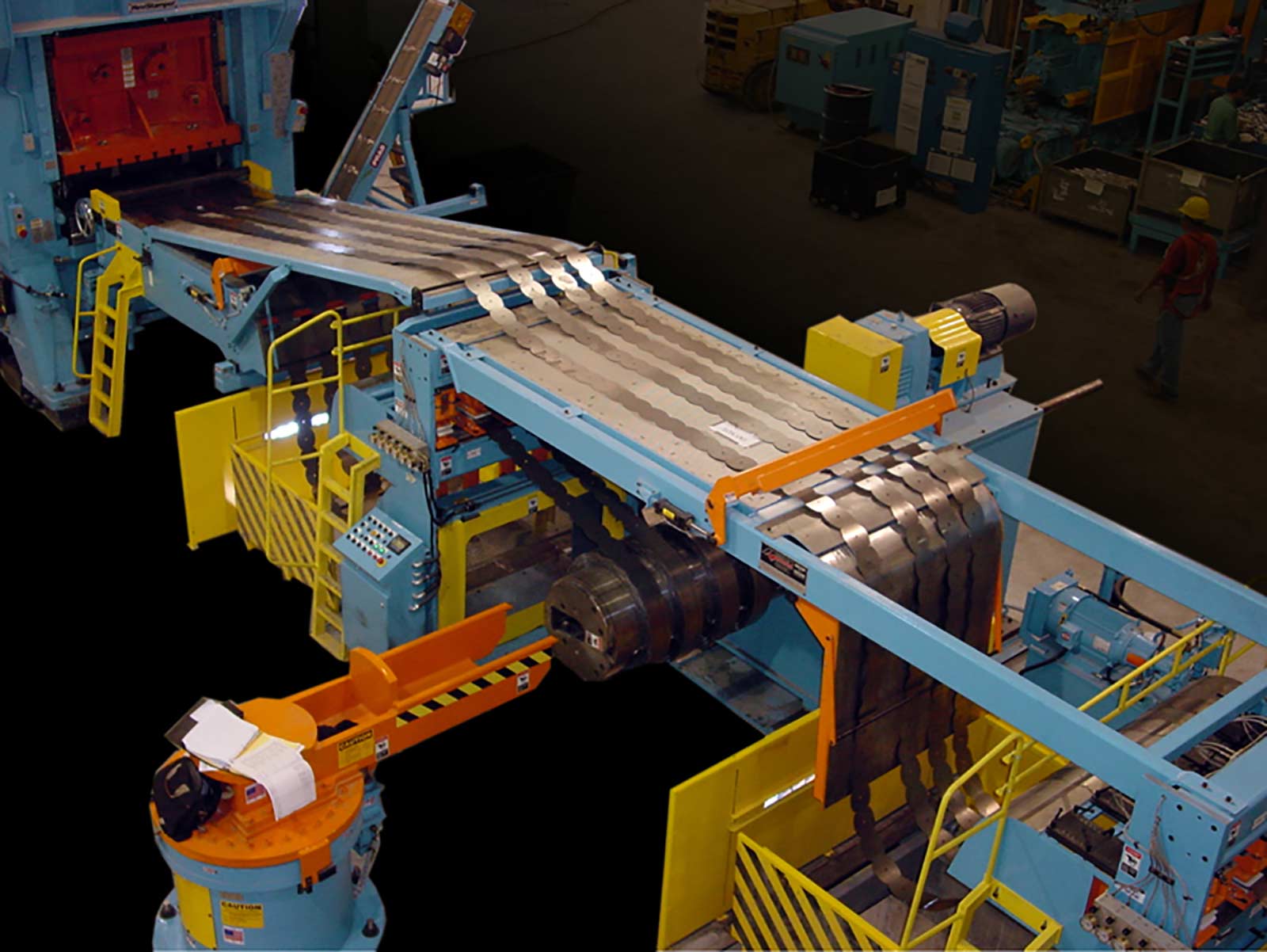

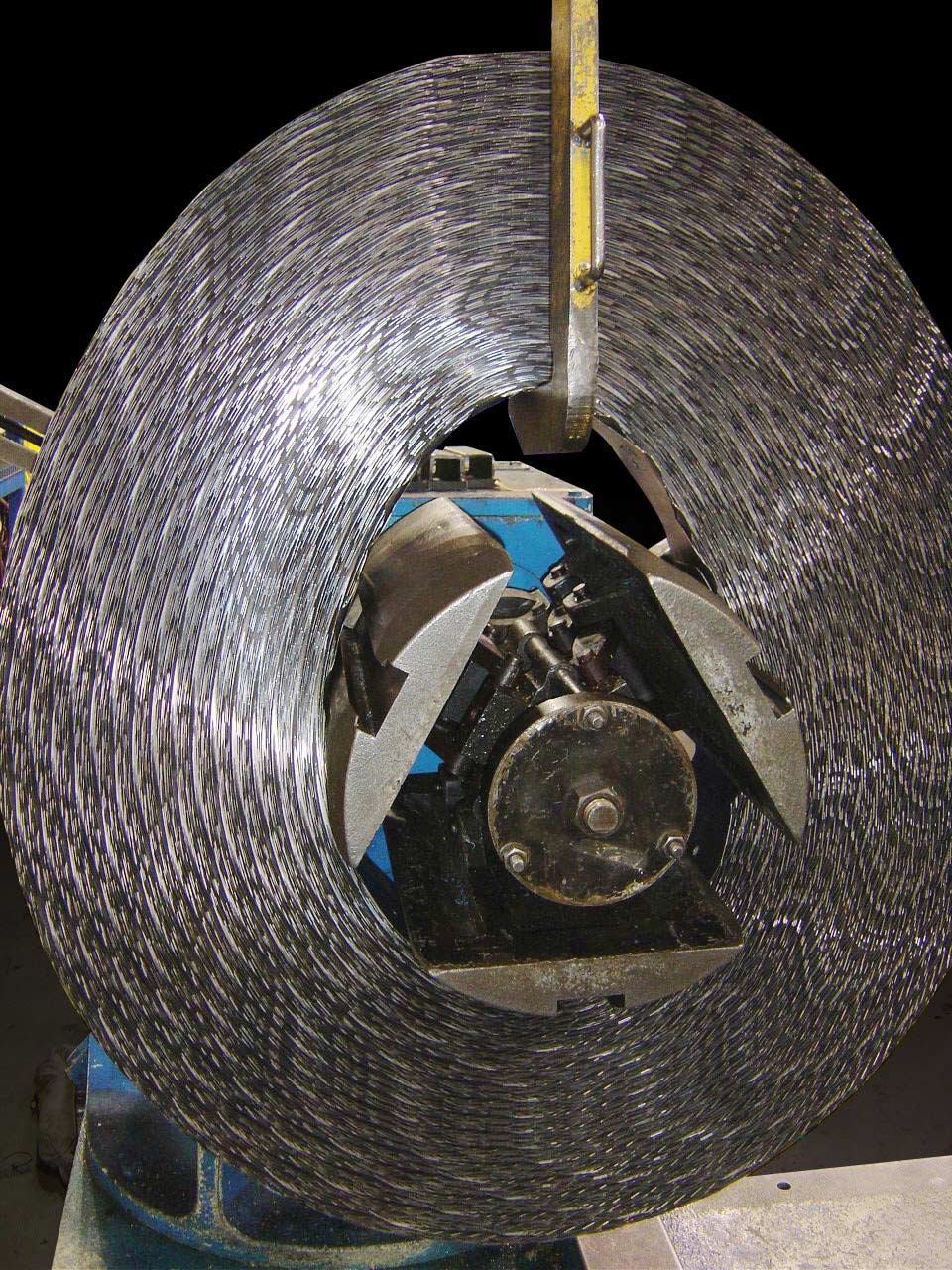

Maintaining proper tension results in straight side wall coils

Machine Concepts Coil Strip – Superior design results in tight coils with proper tension control

Competitor Coil Strip – Inferior design results in improper tension and loose coils