Machine Concepts precision parts straighteners effortlessly achieve extreme flatness in metal parts. This process involves passing the sheet metal through rolls of varying diameters, tailored to the sheet's thickness, to ensure precision straightening. Unmatched levels of flatness, performance and durability are guaranteed for the toughest materials.

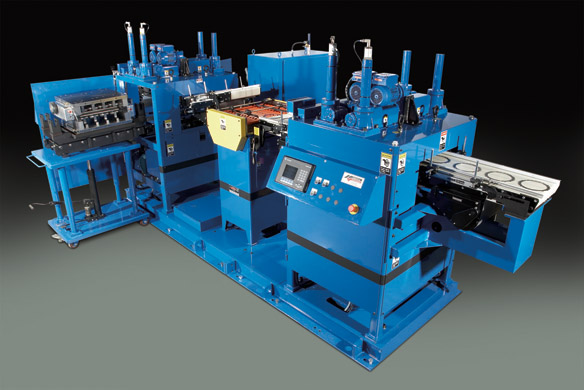

The G2P and H2P series are meticulously engineered to deliver superior flatness and speed compared to other metal parts straighteners. They are offered in single and dual-head configurations, as well as single and double-lane setups.

Challenge the limits with our "Straightening Challenge." Contact us to submit your most challenging metal parts, and witness us achieve flatness beyond your expectations.

Applications include clutch plates, saw blades, food processing knives, laser-burnt parts, and fine blank parts, among others.