State-of-the-Art Solutions for Stacking, Handling & Packing

Our post press automation equipment for Servo, mechanical and hydraulic presses ranges from simple blank stacking to complex post press operations such as automation of mechanical assembly, vision inspection and part organization. We specialize in high-speed stacking, 2D & 3D Vision Systems, part handling and mechanical assembly, robotic welding and joining, inspection and quality control systems.

With Machine Concepts as your partner, we’ll work directly with your engineering and production teams to turn proof-of-concept ideas into reality. Our team will look for the most reliable and cost-effective post-press solution regardless of the press manufacturer.

Our Post Press Automation Solutions Include

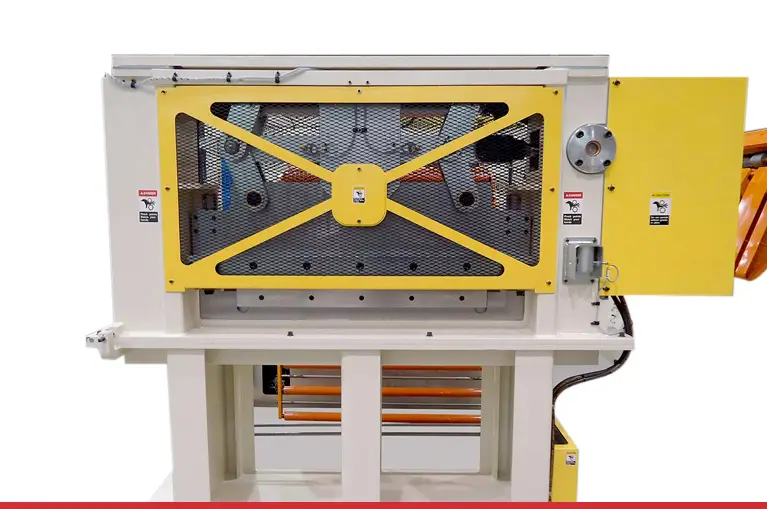

Post Press Precision Parts Straighteners

Clutch plates are blanked in the press and then run through a precision straightener to eliminate any distortions and imperfections after the pressing operations.

Stackers

Our robotic or gantry-style stackers can load empty pallets with finished parts without stopping the press and using multiple bays and conveyor concepts.

Part Retrieval and Scrap Removal Systems

Our retrieval and scrap removal systems are a reliable, cost-effective way of removing parts and scrap from the die.

Scroll Lines

Our scroll lines involve a specialized process to allow motor lamination manufacturers to produce parts with minimized scrap.

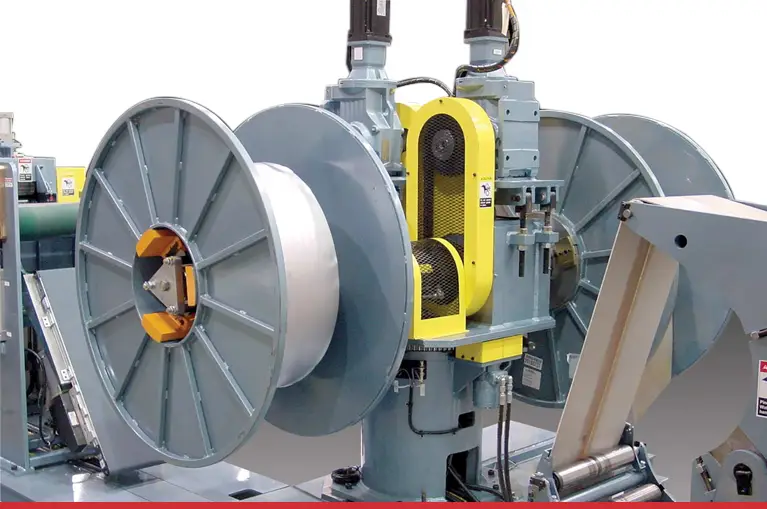

Rewinders

Rewind material after running through a leveler, straightener, slitter or roll coater to further process the coil to achieve the final product.

Shears

Our shears are used in cut-to-length lines to process coils into blanks or press lines to cut material into scrap.