Various options and features can be added to Machine Concepts levelers to further enhance both the leveling process and maintenance operations.

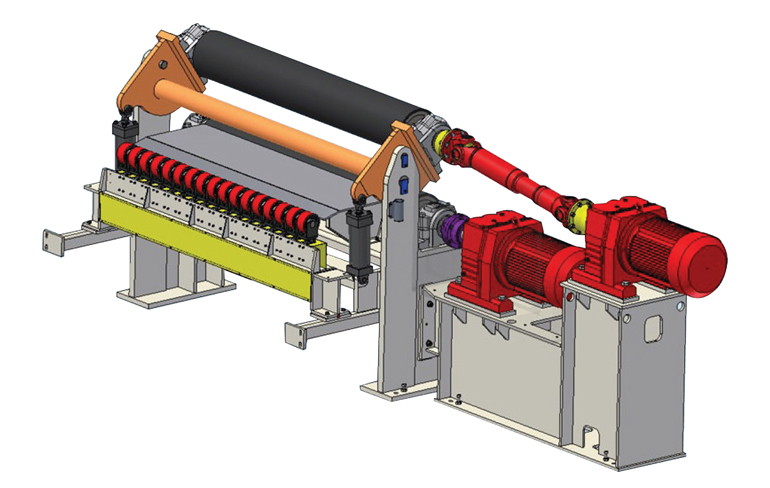

Pull Roll after the Leveler

A pull roll located after the leveler is used for several applications. One is to assist driving material through the leveler when the work roll drive system is near maximum capacity. The pull roll can be used to pull very light gauges through a pull through leveler therefore eliminating the work roll drive system. The pull roll is used for the patented AutoFlat® system to generate the tension zone for the shape sensors to read shape. The pull rolls are available with different roll coverings depending on the application with either the lower or both rolls driven. The design uses a rigid assembly with an equalizer tube to maintain parallelism and hydraulic controls allow for adjustable pinch pressure.

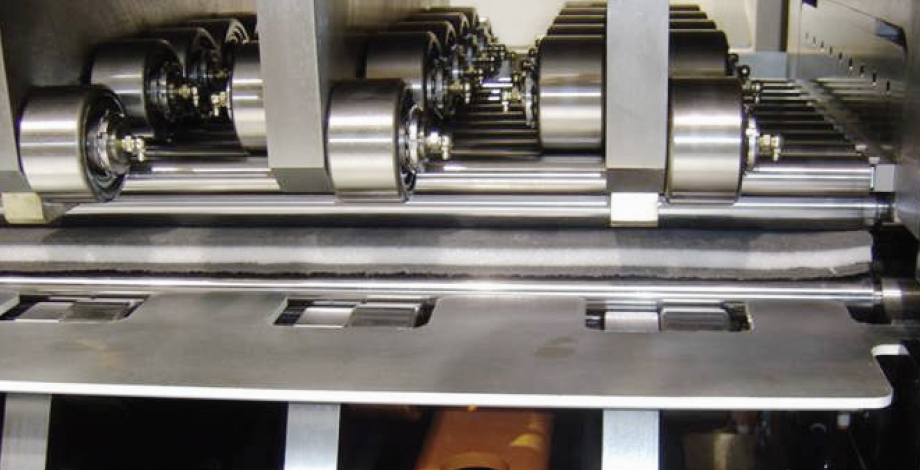

Patented Roll Cleaning System

Available on Any Style Gen III Leveler

The roll cleaning system is a patented cleaning process designed to quickly and easily clean the work rolls. The procedure is to insert a scotch bright cleaning pad assembly into the leveler roll assembly. Then a pushbutton roll clean start will close the leveler to a preset position and scrub the rolls in a back and forth function. Upper and lower rolls run in opposite directions to prevent driving the scotch bright pad out of the leveler. The leveler opens when cleaning is complete.

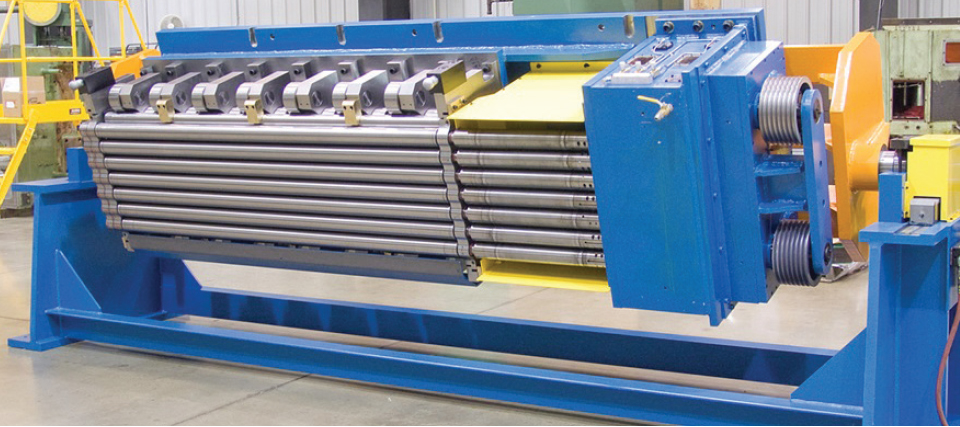

Intermediate Rolls

Available on Any Style Gen III Leveler

Intermediate rolls are available in 5 high and 6 high configurations, and are used for surface critical materials to reduce witness striping from backup bearings.

Chrome Work Rolls

Available on Any Style Gen III Leveler

Flash chrome plating increases surface hardness and reduces adhesion of contaminates, such as oxide pickup, on the roll surface.

Blank Center Speed Control with Laser Loop Sensor

Available on Any Driven Gen III Leveler

The blank center speed control monitors the press or shear stroke rate and calculates the required speed for the leveler. The operator can adjust the loop fill and the laser sensor is used to maintain the loop position.

High Speed Lift

Available on Any Style Gen III Leveler

The high speed lift provides rapid open and close. This option is typically only required for continuous operation coil to coil lines to pass a stitch through with minimal unprocessed material.

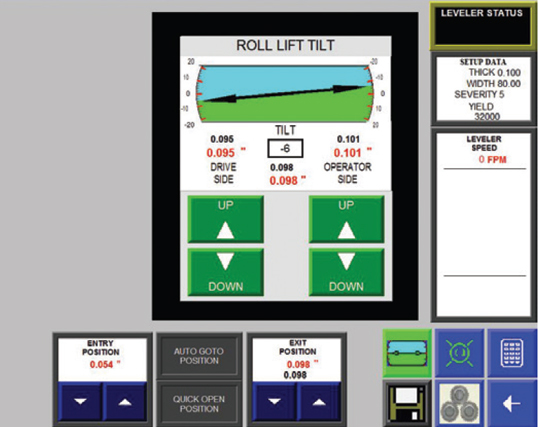

Lateral Tilt

Available on Any Style Gen III Leveler

Incoming strip can have slightly different properties on one edge as compared to the other edge, such as slight differences in thickness, variations in yield strength or even camber. These irregularities can cause the process to be slightly different on one edge versus the other. The crown lateral tilt provides the ability to make minor adjustments to the exit penetration independently from side to side. This is useful to correct one edge curl on sheets when the material properties differ from one edge of the strip to the other.

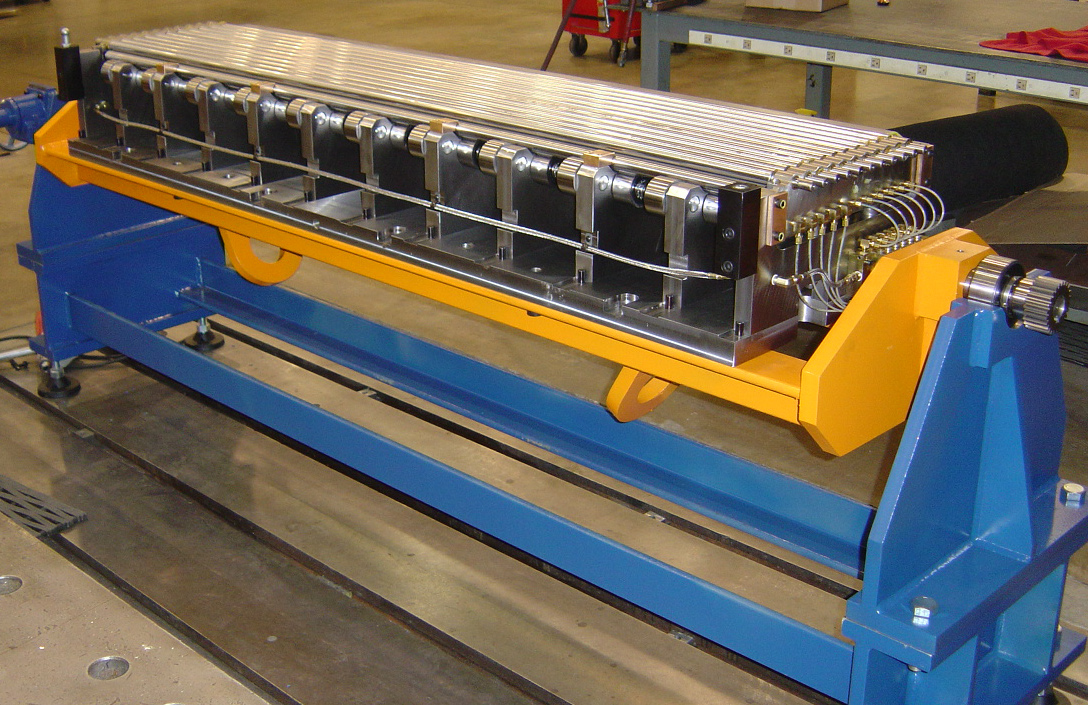

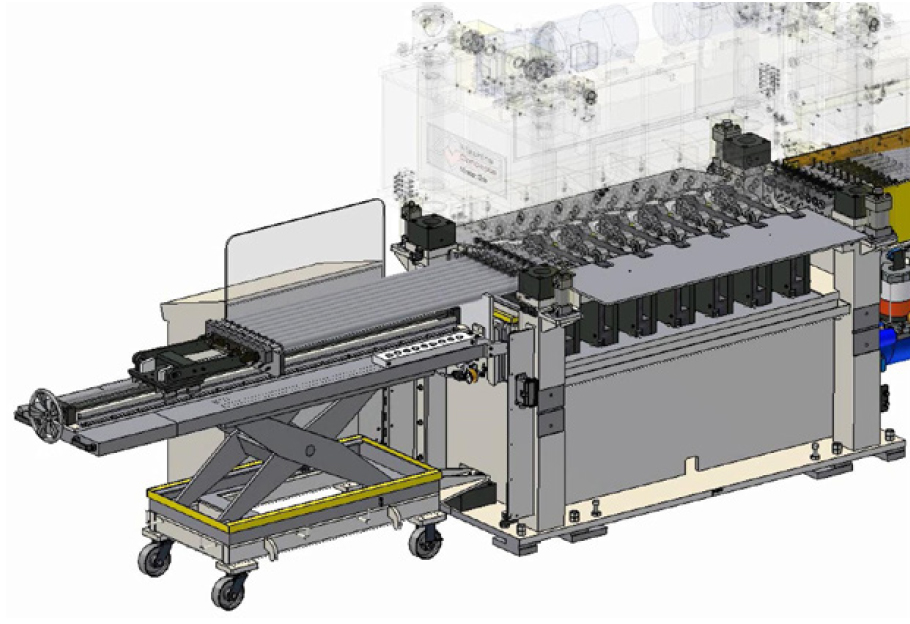

Work Roll Removal Cart

Available on G3B Leveler Only

The work roll removal cart is used with the G3B leveler to extract and install the work roll modules for cleaning and maintenance. The free-wheeling cart has a hydraulic lift function to line up with either upper or lower work rolls. A hand crank mechanism is used to extract/install the work roll module.

Upper Cassette Clamps

Available on the G3DC or G3CC Cassette Style Leveler

The standard method of clamping the upper cassette into the leveler is with bolts. This option replaces the bolts with cassette locking clamps. It reduces time required to exchange cassettes and eliminates the need for the operator to enter the line.

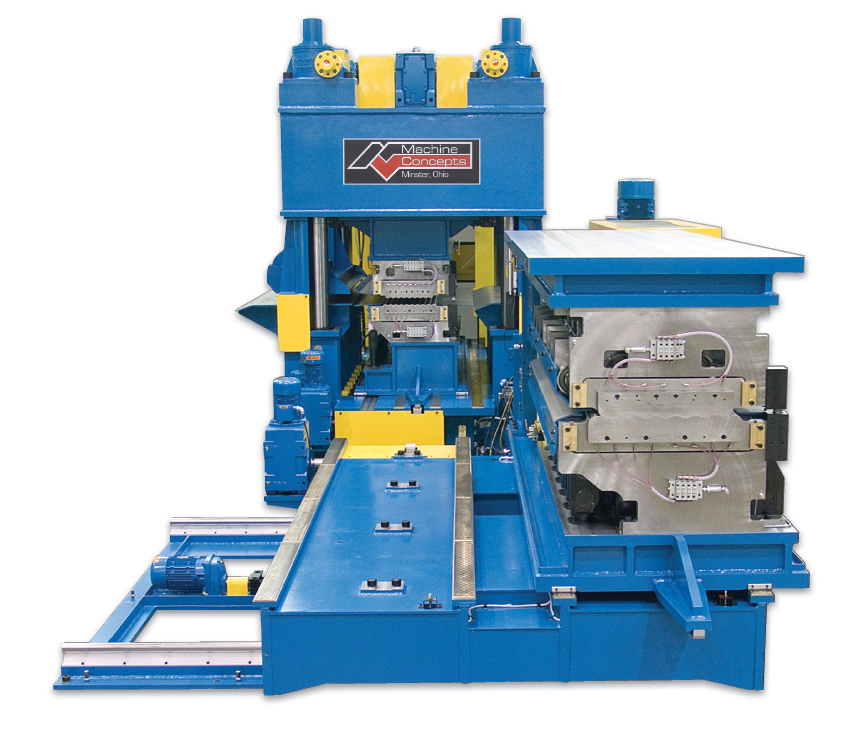

Cassette Exchange System

Available on the G3DC or G3CC Cassette Style Leveler

The cassette exchange system is used to swap cassettes in the leveler and store the unused cassette. The unit consists of a base frame with a two position sliding storage rack. The rack traverse and cassette traverse are powered functions and are pushbutton controlled.

Lifting Bale & Upper Cassette Rotator

Available on the G3DC or G3CC Cassette Style Leveler

The lifting bale is used to lift the upper half of the cassette off the lower half when the cassette is out of the leveler. The base unit provides 180º of upper cassette rotation for cleaning and servicing upper work rolls and backup rails.