Principles of Shape Correction for flat rolled strip and the equipment it takes to do the job!

To correct shape, we need to know the physical properties of the material

What happens when metal strip is worked through rolls? To correct shape we need to know the physical properties of the material.

- Thickness

- Width

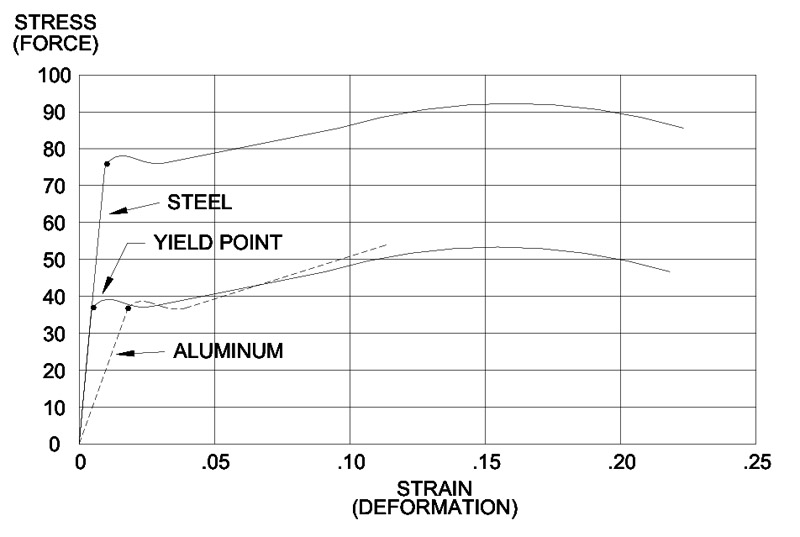

- Yield strength – Stress or force it takes to permanently deform the material

- Modulus of elasticity – Ratio of strain (material deformation) to stress (force on the material)

- Shape defect – Type of defect and severity

To illustrate these material properties a STRESS/STRAIN chart shows steel at two different yield points and steel and aluminum with the same yield point.

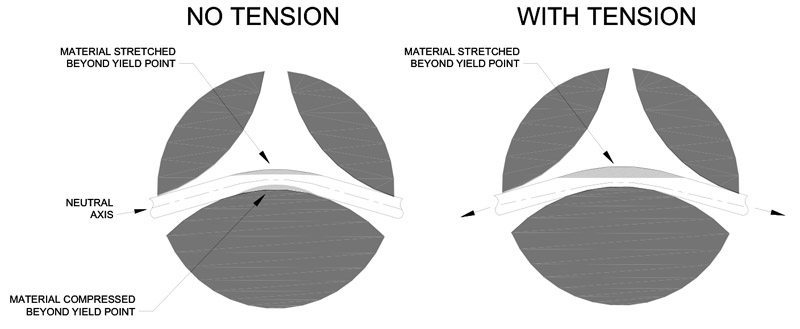

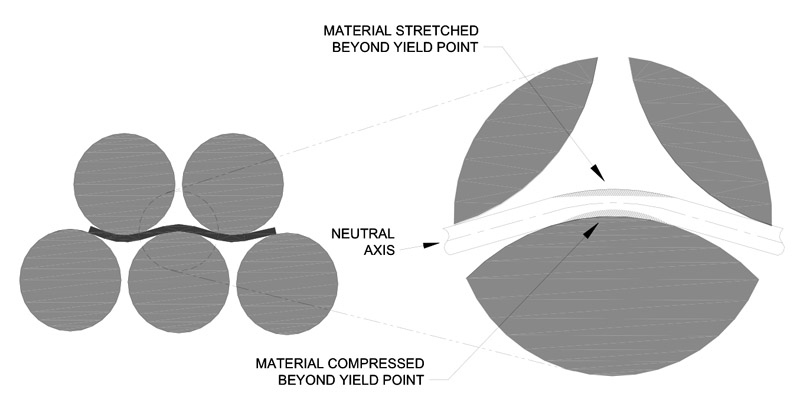

When material is wrapped around a roll or bent into a curve the outer portion is stretched and the inner portion is compressed.

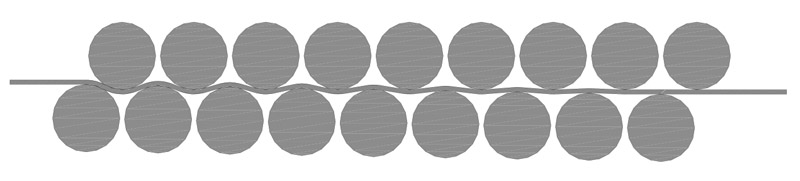

When the strip is under little or no tension the effective bend radius of the material is not necessarily determined by the roll diameter. The bend radius is actually determined by the roll centers and penetration of the work rolls, basically a 3 point arc.

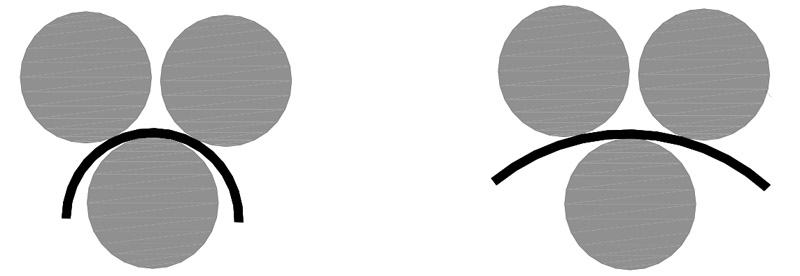

Feathering out the penetration:

Tension of the strip:

- Reduce bend radius

- Tension adds to bending stress

- Shift neutral axis