Machine Concepts has the capacity to design, build, program and install custom automation equipment to meet your production needs. We are poised to take on your most challenging and complex projects. From conceptual design to operational equipment, Machine Concepts will work closely with you to determine the best mechanical or automated solution for your custom equipment and provide seamless support throughout the process. We are dedicated to helping you reduce production costs and improve product quality, operator safety and productivity.

Transform your assembly process with custom-built assembly equipment that increases productivity, reduces labor costs and improves quality. At Machine Concepts, we can design, build, test and install what your factory floor needs to produce the highest quality in the shortest time possible.

Machine Concepts has worked with a variety of laser technology and suppliers to implement retrofitting of existing laser technology and new turnkey laser automation cells. Our focus is to be your complete integration partner for laser applications. We work directly with your team to evaluate, test and recommend the best fit for existing technology, as well as design and build the supporting automation and handling equipment. Machine Concepts will ensure all appropriate OSHA safety compliance, light guarding and risk analysis are completed prior to factory acceptance testing at our facility. Our technical capabilities and experience include laser marking, laser welding systems, conventional welding systems, part handling, part inspection, and 2D & 3D vision systems.

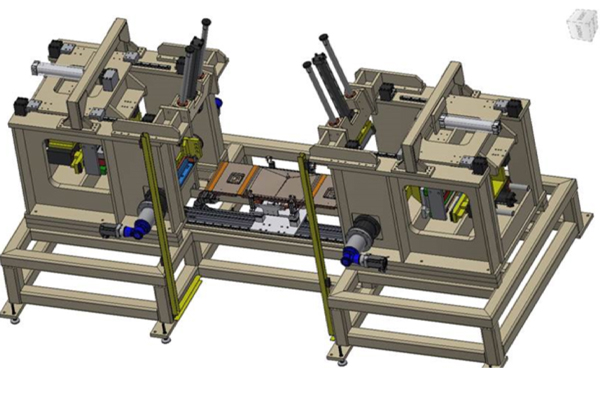

Machine Concepts works directly with your development and engineering team to turn proof of concept products into an automated process. Our technical knowledge in metal forming, post-forming inspection and assembly, as well as surface critical parts handling systems, makes us an ideal partner for both individual metal forming equipment and completely automated metal forming and product assembly lines. Machine Concepts specializes in metal forming equipment for surface critical consumer products and complex geometry metal forming.

Machine Concepts combines our capabilities in part handling, vision systems and machining knowledge to create automated machining systems capable of outperforming human-operated systems. We focus on creating custom process tooling systems with the flexibility and capability to evolve as your products change over time. All custom equipment is factory tested and approved by you prior to onsite installation.

Laser marking is becoming a common method for part identification and tracking. Whether it is a standalone unit or integrated into surrounding automation, Machine Concepts can custom design, build, program and integrate a CDHR-compliant laser marking system to meet your needs.

Heavy-duty custom conveyors can consist of multiple components, including straight sections, turntables, rollovers, integrated lifts and many more. Machine Concepts can design and build all components to meet production needs and integrate them with other equipment for smooth flow.

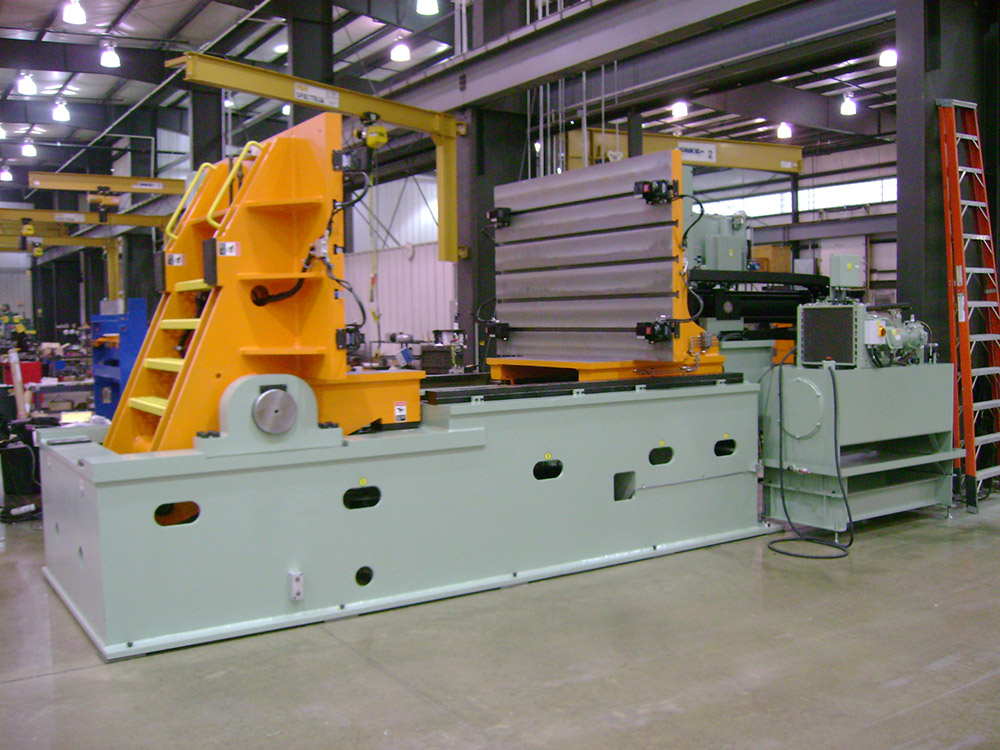

Machine Concepts will custom design and build a heavy-duty die inverter to meet your production needs. The die inverter machine shown hydraulically pulls dies apart and has the ability to rotate one die half 90°. It has a separating force of 40 metric tons and is rated for dies weighing up to 25 metric tons.

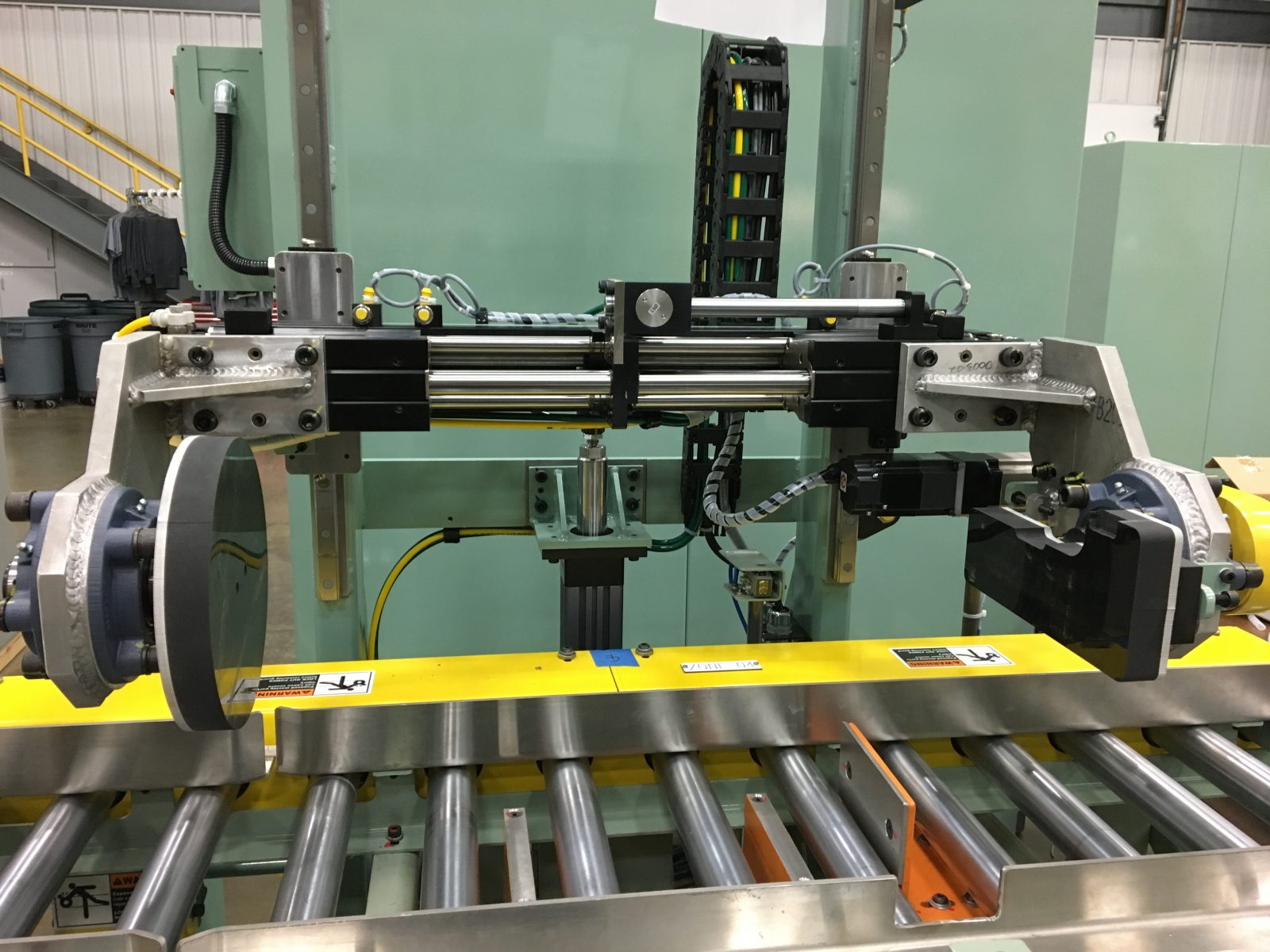

Small inside-diameter pipe welds are difficult and even impossible to grind by hand. Machine Concepts designed a portable pipe grinder that will roll into the pipe and extend up to match the diameter. With the pipe rotating, the grinder will grind the weld down smoothly to the inner wall of the pipe.

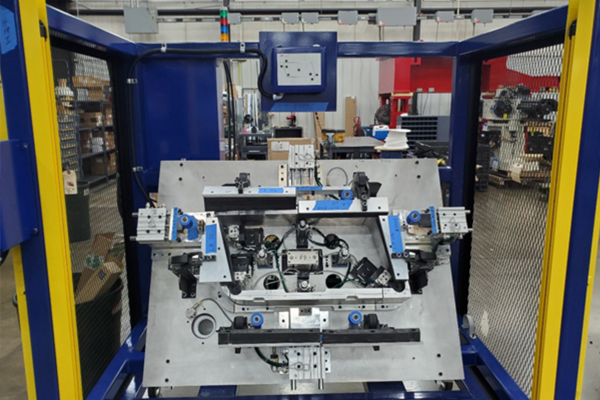

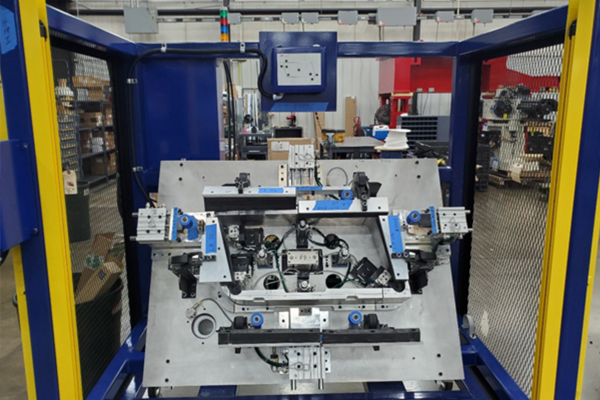

Some processes during production require the workpiece to be located and clamped. Machine Concepts will study the workpiece closely for opportunities to locate and clamp without affecting the quality of the end product. We can also allow access for a robot, EOAT or manual loading and can design and produce 3D machined parts to your needs.

Part shakers can be used to remove machining chips or other unwanted particles from workpieces. The shaker pictured has a custom fixture plate that can be removed via quick disconnects for quick model changes.

Reducing cycle times is a key driver for automation. This automatic reamer designed and built by Machine Concepts processes the part through three stages of reamers, reducing cycle time while maintaining linear product flow.

Part manipulation can range from complex to simple. We used multiple different methods on this oiler to separate and orient the parts for correct oil coverage.

Part cleaning can be a difficult process. Machine Concepts designed and built this oil slinger to remove excess oil from a gear during its machining process. This design can be customized to fit your part and available machine space.

Repeated part handling can be an ergonomic nightmare. This part manipulator with intuitive joystick controls allows for each part to be inspected by an operator without requiring them to physically lift and rotate each part.