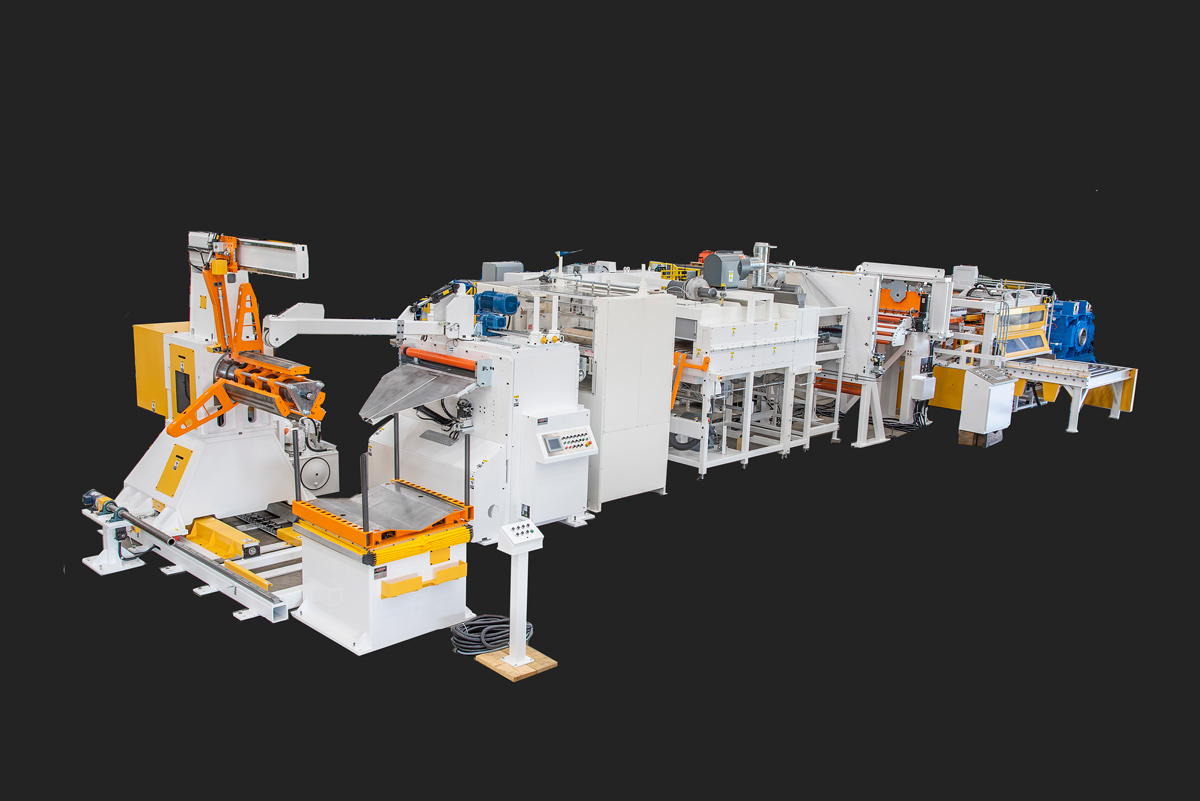

Machine Concepts Press Room group provides custom processing lines to those in need. If you require a custom process line and off the shelf solutions are not adequate for your application, Machine Concepts is here to help. We have the engineering capacity to help you evaluate upgrading your existing process line, as well as the design and build capability to help you start from scratch with a new turnkey line.

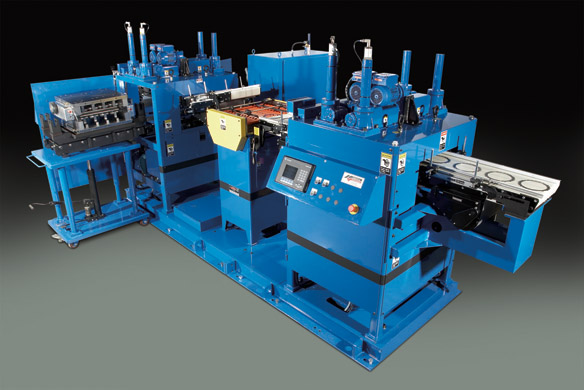

Scroll strip stamping is a creative way to scroll slitting lamination material of circular or hexagonal parts. During this process, a reduction of 12% to 29% can be achieved over straight slitting material. This process also controls the position of one part to another part very accurately that normal scroll slitting arbors cannot maintain. The end result is cost reduction of scrap for large motor lamination stampers

Machine Concepts focuses on cut to length lines requiring absolute perfection for surface critical components.

Achieving unsurpassed levels of flatness with proven performance and durability for today’s toughest materials. Both the G2P and H2P series have been designed to obtain a level of flatness and speed that many other parts straighteners cannot achieve. Take the “Straightening Challenge.” Send us your poorest quality, toughest part and we’ll achieve a level of flatness that you’ve never imagined.

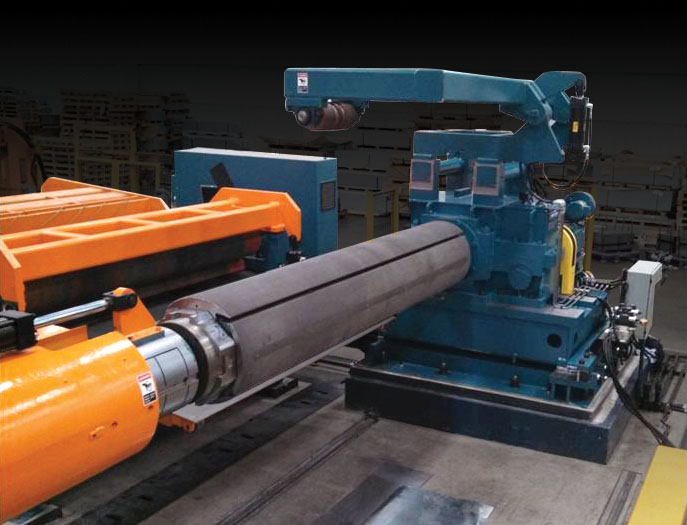

Machine Concepts’ Gripping Mandrel allows the operator to place the lead edge of the coil onto the mandrel slot and when the operator expands the mandrel, a gripper bar compresses the lead edge within the slot. The operator jogs roughly two wraps of material on the mandrel before placing the rewind in automatic run mode and pulling high tension.

Our Belt Wrapping Mandrels allow customers to wrap material on a core diameter or coil spool. The operator places the core on the mandrel and expands the mandrel to size.

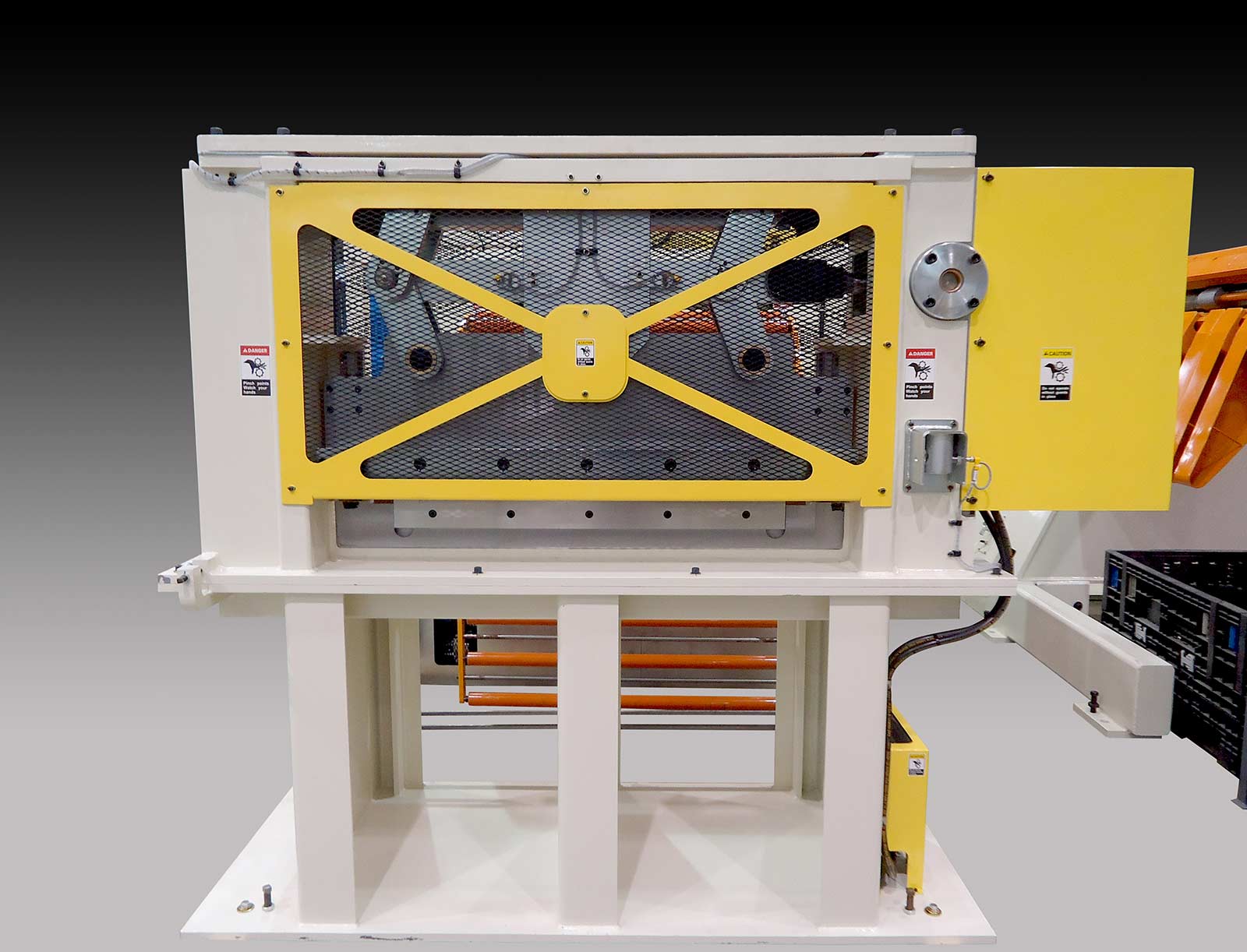

Machine Concepts Toggle Shear has been proven in the field for over 10 years as one of the fastest non-servo-driven shears in the industry.

- High Efficiency Toggle Action

- Full Force Near Bottom of Toggle Movement

- Bowtie Toggle Crop Shear – Extension

- Bowtie Toggle Crop Shear – Retraction