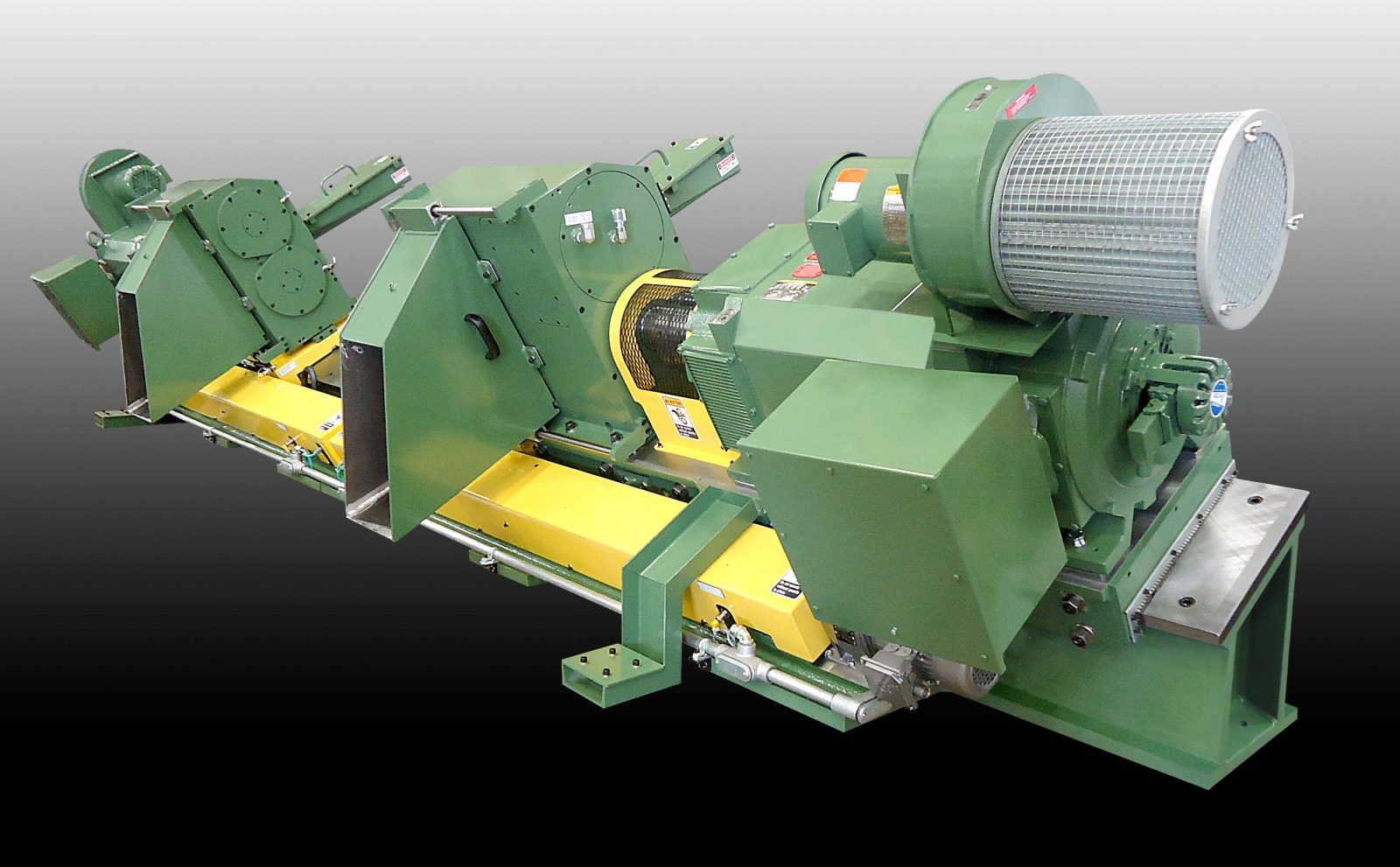

Machine Concepts builds a full line of slitters for applications in finishing and cut to length lines.

- Drop-in self-contained heads to replace or be interchangeable with existing slitters

- High precision heads for light gauge, high-speed lines running aluminum, steel and red metals. Standard sliding outboard housings or optional swing-out housings for better access to tooling

- Complete sets of tooling available including precision spacers, knives, stripper rings and hydraulic nuts

- New retrofit slitters designed to be compatible with existing scrap handling systems

At Machine Concepts our standard procedure is to test run and fully inspect all slitters and side trimmers at our facility prior to shipment. Thermal arbor growth is measured and recorded to ensure machine performance once installed. Arbor endplay, radial runout and tooling shoulder runout are also checked and held within tight tolerances. All machine inspections are fully documented and included in our service manuals.

- Heavy-duty, rugged cast or steel housings

- Synthetic grease-lubricated arbor bearings for low operating temperatures

- Full-length eccentric sleeves for knife overlap adjustment. Passline remains constant at all knife diameters.

- Scrap chutes or diverters

- Hydraulically expanded hub cutter/knife holders

- Motorized knife overlap adjustment

- Swing out outboard housings for better access to tooling

- Complete sets of tooling including precision spacers, knives, stripper rings and hydraulic jet nuts

- Slitter fixed bases with manual or automatic lockdown clamps

- Custom slitter drives with manual or automatic coupling engagement

- Slitter storage trays – rotary or lateral shift.

- Scrap storage or scrap pit enclosures

- Slitter tooling capstans and tooling exchange systems

- Slitter tooling racks and storage crates

- Scrap choppers

- Scrap ballers

- Fixed slitter base designed for easy, quick and accurate exchange of slitters or side trimmer heads.

- High precision slitter with super finished arbors that are capable of accepting hydraulic hub cutters/knife holders or standard packed arbor tooling.

Machine Concepts designs and manufactures a full line of hydraulically expanded, self-clamping slitter and side trimmer hub cutters/knife holders. These hubs are high precision, have excellent holding power, are easy to use, and are ideal for quick tooling setups or changes.

Machine Concepts designs and builds several types of side trimmers for applications in mills, cut to length lines and high-speed finishing lines to fit our customer’s needs.

- Drop-in, self-contained head assemblies to replace or complement existing slitters

- High precision heads for light gage, high-speed lines running aluminum, steel and red metals

- Traditional finishing and cut to length lines

- Hot mill side trimmers

Many heads include custom control packages – stand-alone or with communication and automatic setup capability.

Many new side trimmer systems can be compatible with existing scrap handling systems.

- High precision bearing setups specialized for your application

- Horizontal knife gap adjust packages

- Manual adjustments or automatic setup via onboard PLC controls

- Retrofit packages to replace existing slitter heads

- Stand-alone direct drive system or designed to use your existing drive

- Turret side trimmers for process and pickle line applications

- High precision SAE 4150 flame hardened arbors. Arbors designed for fixed knife cutting edges. No shimming required when face grinding/sharpening knives.

- Synthetic grease-lubricated arbor bearings for low operating temperatures

- Vertical knife overlap adjustment via full-length eccentric sleeve

- Motorized width adjust via precision ball screws

- Appropriate thread tables

- Scrap chutes or diverters

- Lifting taps and burnouts provided in all equipment

- Hydraulically expanded hub cutter/knife holders

- Adjustable head toe in or “Cant”

- Motorized knife adjustments both horizontal and vertical

- High precision horizontal knife adjustment accurate to +/-.0002 inches. These adjustments can be made on the fly while the head is cutting strip.

- Heads driven via one common drive shaft or individual drives on each head

- Entry bridle systems

- Digital readout for position feedback

- Automated “Go To” positioning for width and knife gap/lap adjustments

- Complete sets of tooling, including precision spacers, knives, stripper rings and hydraulic jet nuts

- PLC Controls with full communication capability

- Automatic “Go To” knife gap, knife overlap and outgoing sheet width control packages available

- Digital position readouts and/or HMI display screens

Machine Concepts specializes in custom-designed scrap choppers to accommodate all your slitting and side trimming scrap handling needs. Our capabilities include new machine development, upgrades and retrofits into existing lines.

- Dual drum with raked blade cutting action – optional straight blade available

- True elliptical knife profile to maintain constant knife clearance throughout the cut

- Each knife has four cutting edges

- Quiet operation and reduced peak drive torque

- Arbors supported on both sides of cut via precision tapered roller bearings

- Easy access, setup and maintenance of knives

- Customized self-threading scrap chutes

- Broad gauge range with no setup change

- Shorter scrap lengths

- Anti-backlash helical gearing

- Heavy-duty welded steel housings

- New machine development, upgrades and retrofits into existing lines and/or installations