Customized Solutions Fit to Your Production Needs

Custom Automation Equipment requires an integration partner with the experience to get it done right. At Machine Concepts, our specialty is innovative solutions that increase productivity and quality, decrease production costs and improve safety.

Machine Concepts works directly with your development, engineering and production teams to turn proof of concept products into automated process equipment. Our team will look for the most reliable and cost-effective solutions, whether that includes a robot or not. Our job is to see you succeed.

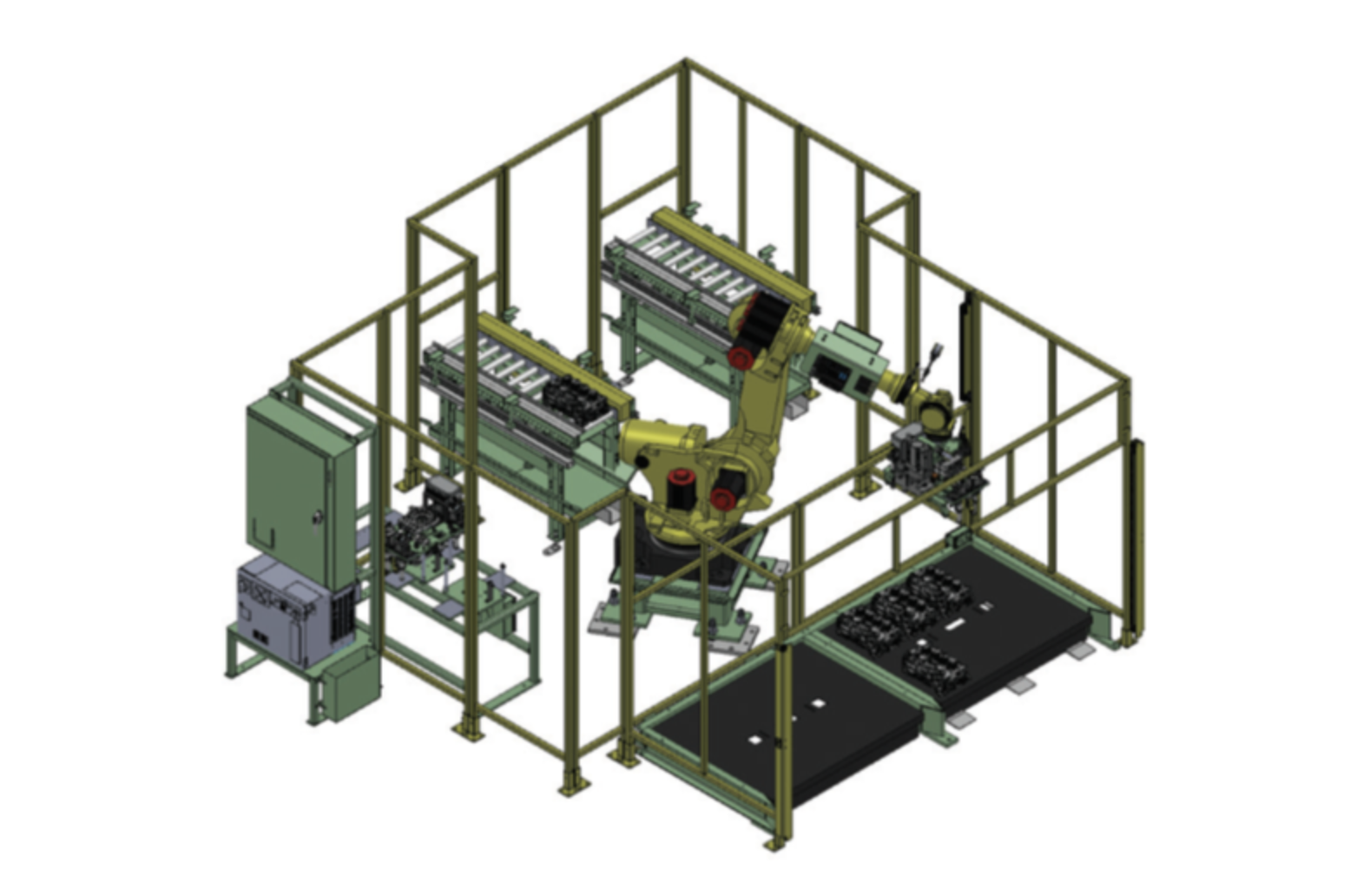

Robotic Integration

Machine Concepts has the capacity to design, build, program and install medium-sized robotic lines. This video shows a line with multiple robots and supporting equipment designed and built by Machine Concepts. We also worked with other OEM suppliers to integrate their equipment with our automation during installation at the customer’s facility.

Part Handling Systems

Automating both incoming and in-process parts handling can increase line productivity and reduce labor costs. Machine Concepts specializes in custom part handling solutions to fit within existing parts manufacturing processes. Quality and tolerance inspection can be incorporated to these systems to get rejected product removed from the process line sooner and with better speed and consistency than manual inspection.

Robotic Welding and Joining Systems

Robotic welding and joining systems require an integration partner with the experience to get it done right. Machine Concepts works directly with your development and engineering team to turn proof of concept products into an automated process. Our technical knowledge in metal forming, laser and conventional welding technology, as well as vision systems, makes us an ideal partner for turnkey robotic welding and robotic assembly systems.

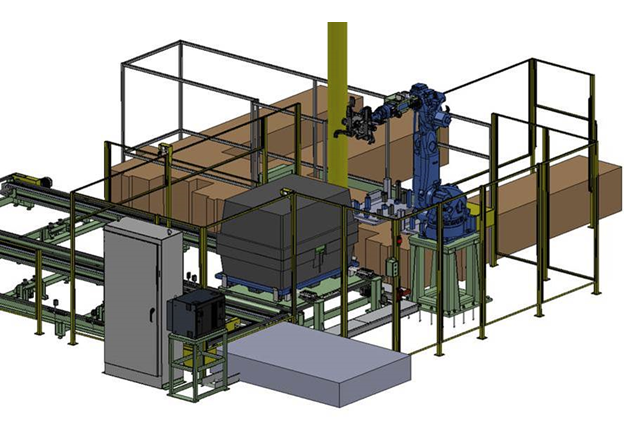

2D & 3D Vision Systems

2D & 3D Vision Systems are the cornerstone of our robotics and automation solutions. Complex part geometry, surface critical component handling and irregular parts presentation all require automation solutions capable of recognizing when, where and how to interact with your parts and your process. Additionally, 2D & 3D recognition allows Machine Concepts to implement multi-step automation operations into one complete cell. This capability can also eliminate the manual labor associated with part presentation to the robot cell.

Shown is the use of 2-D vision with a Yaskawa Robot to automatically open the part storage latch mechanism and lid, recognize what type of parts are enclosed and where to pick, and remove and dispose of the packing material. Vision integration allows this solution to handle multiple part SKUs and evolve over time as new parts and product evolutions are incorporated into the process line. This system also incorporates bar code scanning and integration with the end-user's lot tracking and quality system. The solution was installed and integrated into the existing line in just four days.

Robotic Assembly/Inspection/Quality Control Systems

Robotic Assembly is complex. Machine Concepts has the experience to automate complex multi-step assembly processes. We pride ourselves on our ability to create solutions for demanding applications other suppliers would walk away from. Delivering automated solutions that others believe cannot be automated is what drives us. Our history in custom-designed process equipment allows us to solve problems existing equipment isn’t capable of handling. Past project examples include engine transmission assembly, automotive component assembly and installation, turnkey stamping integration and assembly, post-press part organization-banding-packaging.

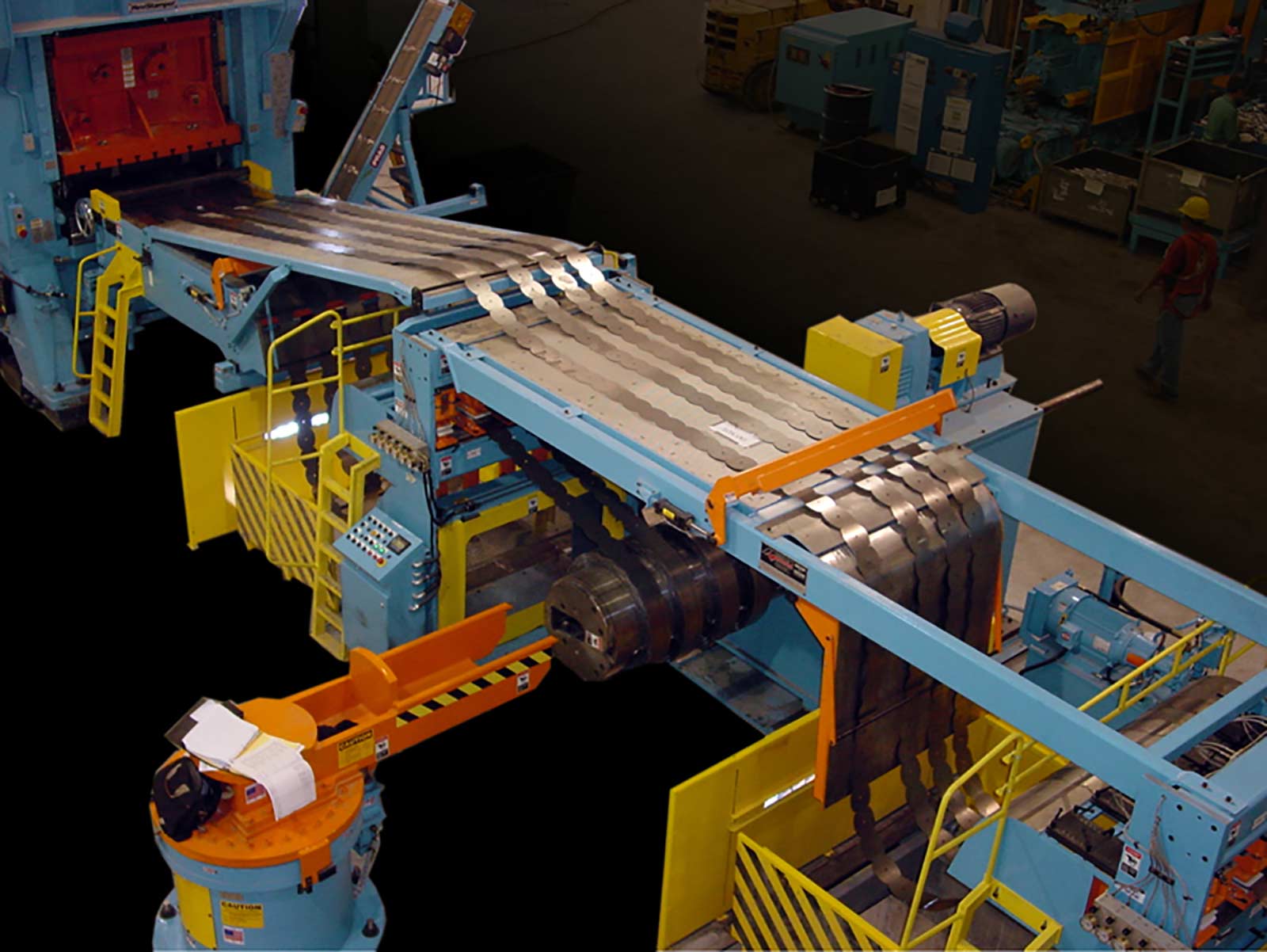

Press Automation

Machine Concepts can be your complete press room integration partner. Whether you’re looking for press feed equipment, complete press production lines or custom post-press automation equipment, if you are stamping parts, we can help.

Core competencies include: press feed lines, shape correction systems, press to press transfer systems, stacking systems, and post-press part organization, banding and packaging.

Typical applications include: high strength automotive aluminum and steel, electric motor laminations, surface critical appliance and consumer products, general contract stamping equipment, industrial and commercial appliance equipment, and lawn, garden and farm equipment. Discover our Press Room solutions here.