Deliver Parts Faster and More Efficiently

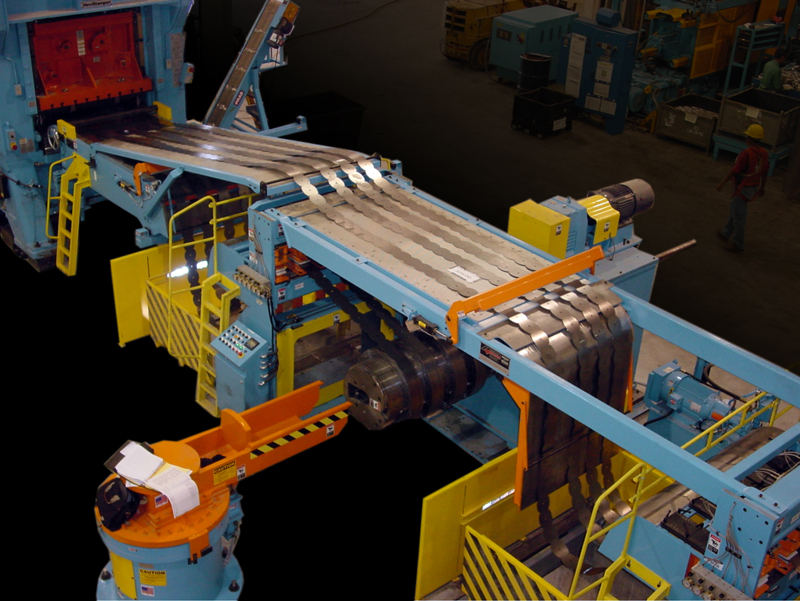

Our before-the-press solutions for Servo, mechanical and hydraulic presses are customized and focused on automation to help deliver parts faster, more efficiently and more profitably. At Machine Concepts, we are known for taking on challenging projects that involve high-speed, surface-critical, tough-to-process materials and applications.

In coordination with our automation group, our press room engineers work directly with your engineering and production teams to turn proof-of-concept ideas into reality. Our team will look for the most reliable and cost-effective solutions regardless of the press manufacturer.

Our Before-the-Press Solutions Include

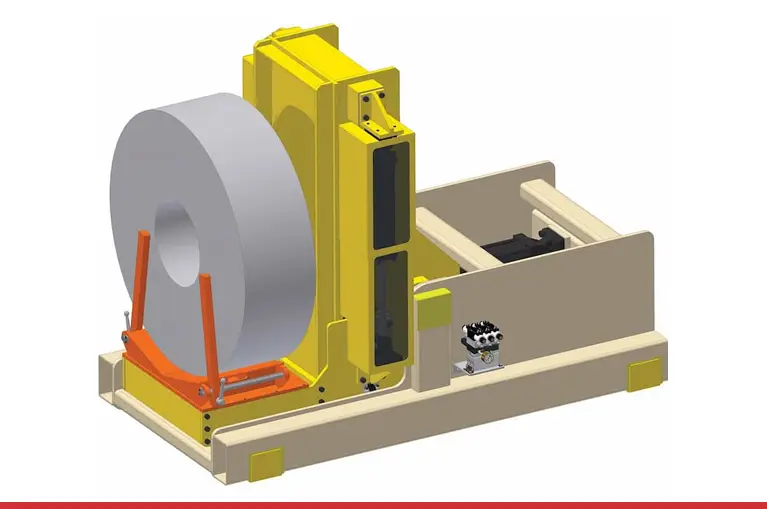

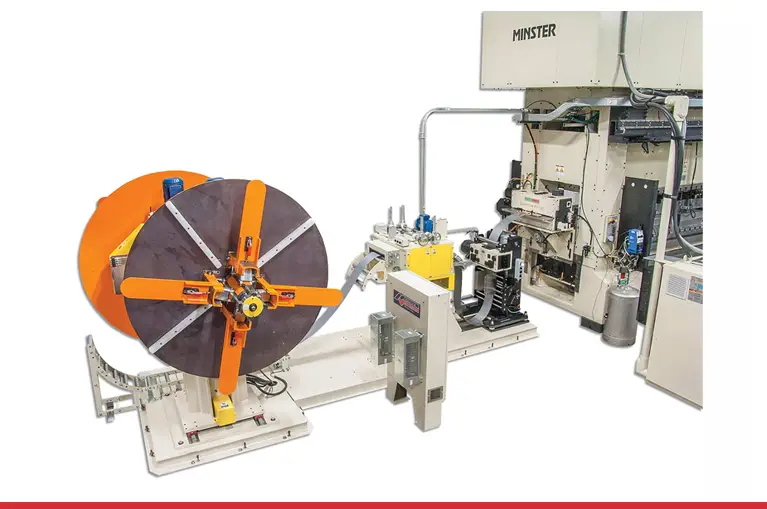

Decoilers

Precision Straighteners

Flatteners

Shape Correction Levelers

S-Loops

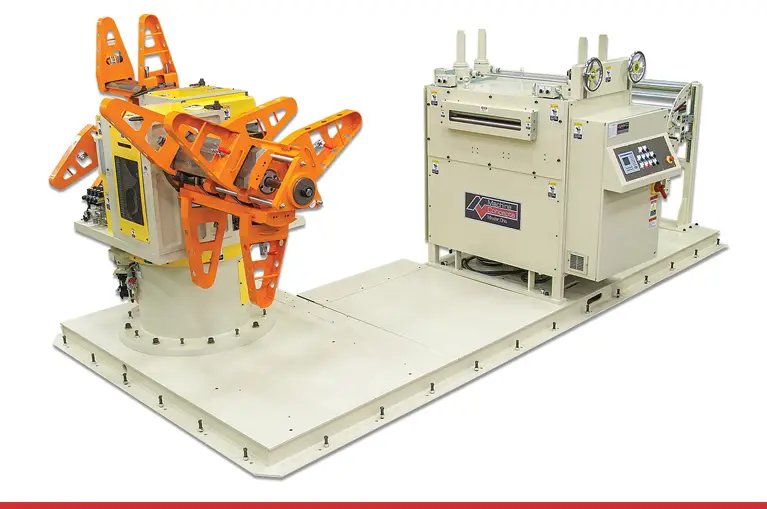

Destackers

Upenders

Coil Cars & Coil Stands

Precision Roll Services

EV Precision Straighteners

Automating a Press Feed Line

Integrating automation into the press feed line enhances productivity from the start. With Machine Concepts as your partner, you can efficiently integrate automation into your press room operations and experience the benefits for years to come.

- Enhanced Production: With the right automation in place before the press, the entire stamping process becomes more streamlined, leading to increased output.

- Optimized Performance: Our before-the-press solutions ensure that materials are presented to the press in the best possible condition, reducing the risk of defects and enhancing overall quality.

- Cost Efficiency: By maximizing performance and reducing manual labor before the press, significant cost savings add up from the start.