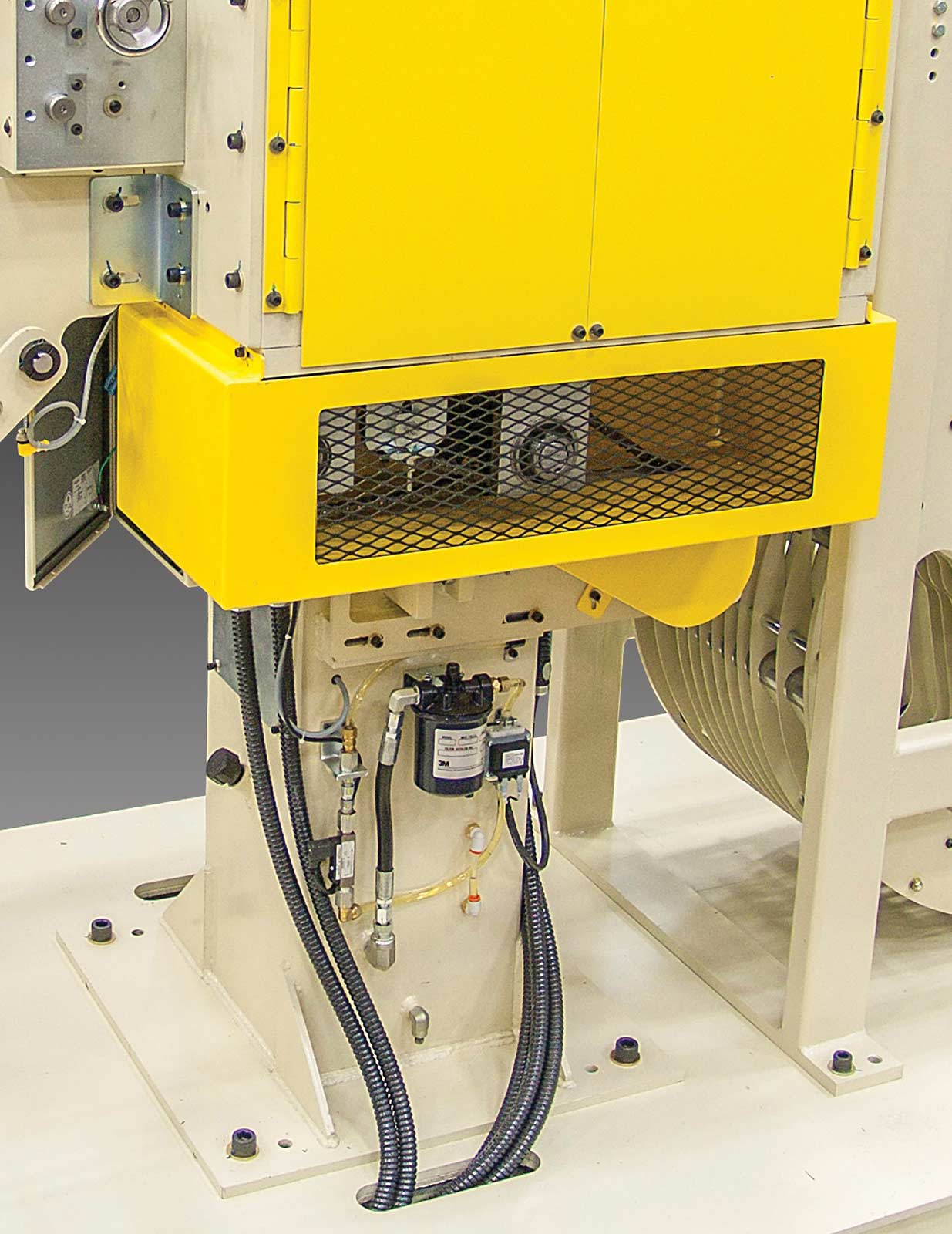

EV/L2

Electric Vehicle Precision Straighteners

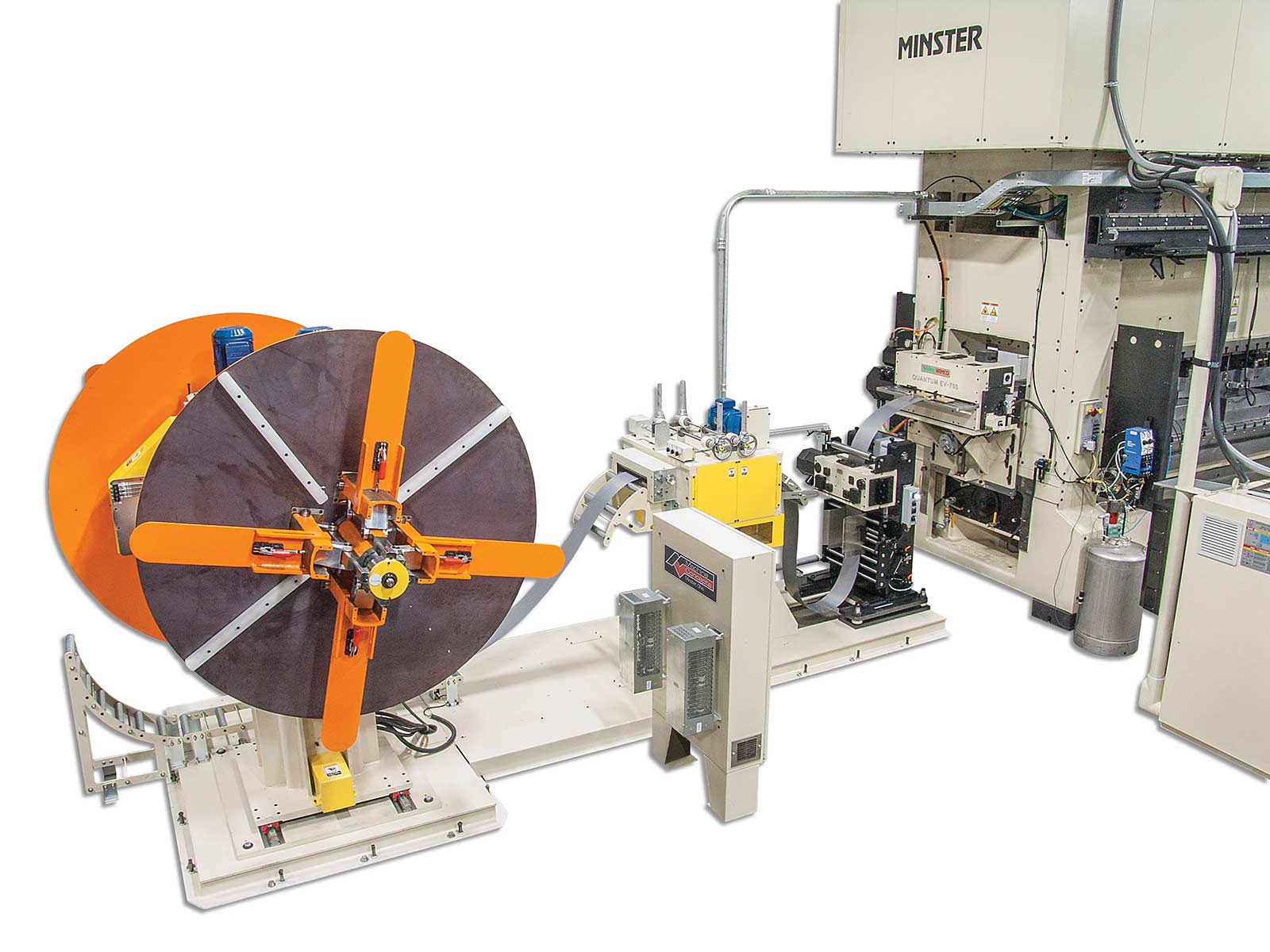

The EV/L2 family of straighteners have been designed for lighter gauges (.008” to .039”) and normally higher speed applications (400 FPM). Features include easy removal of roll cassettes and interchangeable roll cassettes with different roll diameters within the same base frame.

The EV/L2 series is designed specifically for electric vehicle market materials. This machine is capable of straightening thin gauge, high strength material through a compact, efficient machine design. Utilizing a pull roll, the EV/L2 straighteners can accomplish improved flatness compared to other precision straighteners.

EV straighteners remove basic shape defects in a coil strip (such as coil set and cross bow) and can reduce the amount of edge wave and center buckle to some extent.

Electric vehicles are quickly emerging as a more efficient alternative to conventional combustion engine driven vehicles. As the range, efficiency and battery life increases, the demand for electric vehicles is constantly growing. Also, with advancements in technology, consumers expect electric motor driven features to be included in the most standard versions of most new vehicles. Machine Concepts has developed the EV/L2 Precision Straightener to meet the demand for more electric motor laminations used specifically in electric vehicles.

Applications: Electrical lamination material, high strength thin gauge stainless steels, laminated materials, electric vehicle laminations.

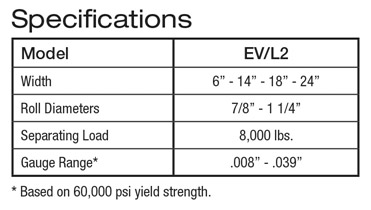

Roll Cassette Access

The roll cassette is easily accessible and removable from two sides of the machine. Roll cassettes can be interchanged with different roll diameter cassettes to accommodate a wide range of materials and thicknesses.

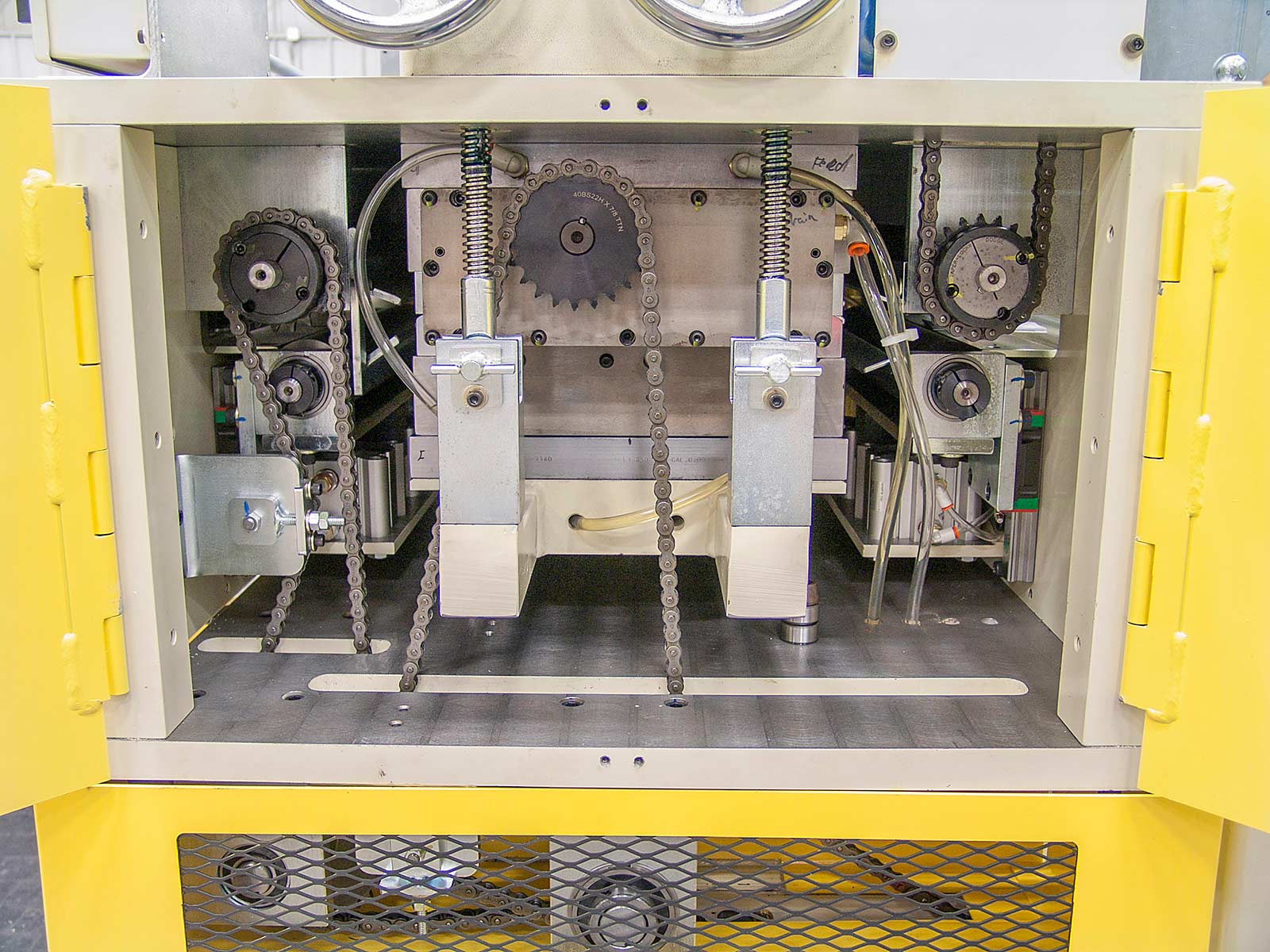

Lubrication Pump and Fluid Reservoir

The lubrication system provides continuous flow of light oil to the journal bearings and gear mesh. A lubrication monitoring system is incorporated to protect the machine in the event of no oil flow, a block in the filtration system, or a low fluid level in the reservoir. The reservoir is built into the frame of the machine with only a filling nozzle visible for a clean, compact design.

EV DM/SM Decoiler & Loop Control

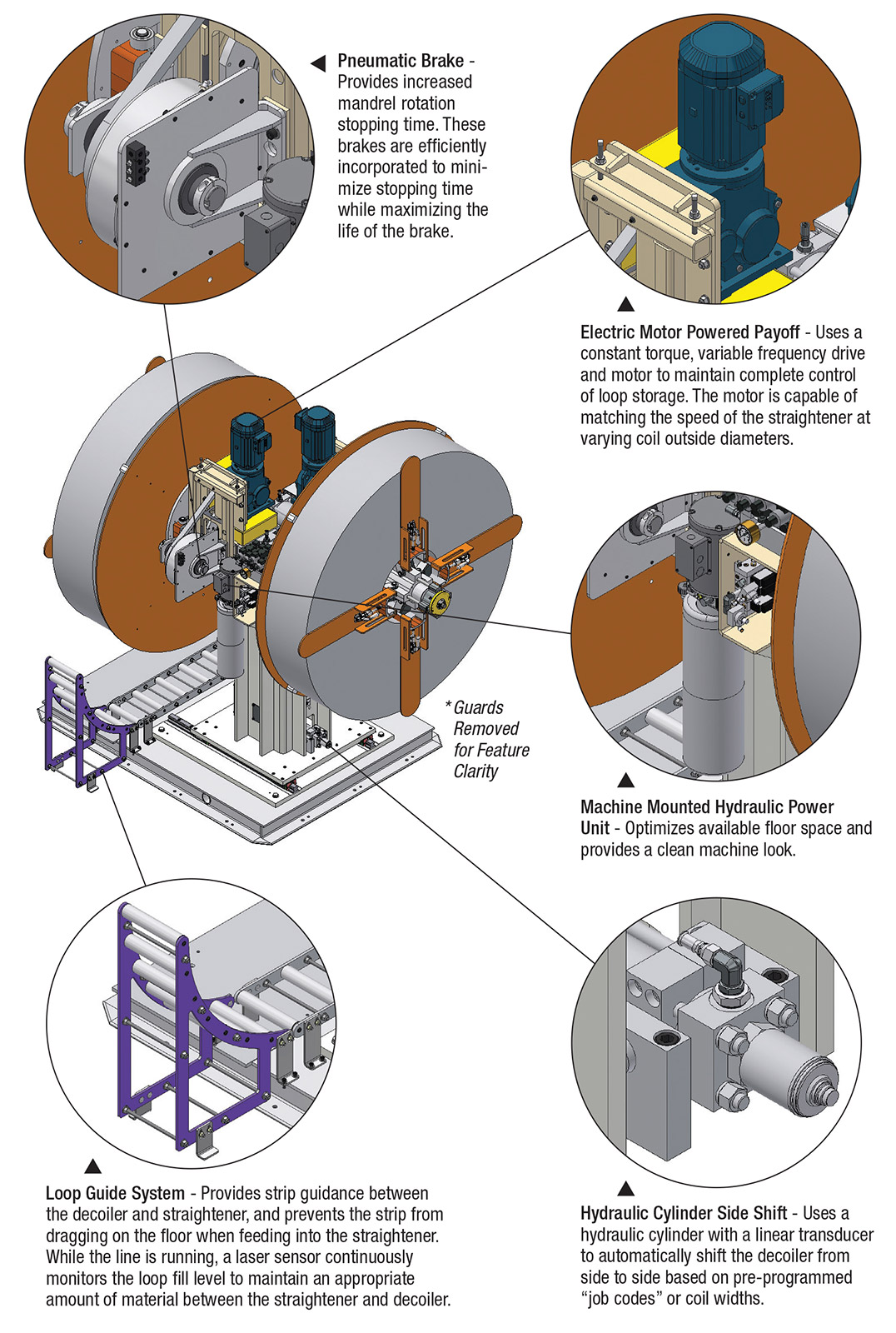

Decoilers incorporated on EV lines are, many times, required to have an electric motor powered payoff feature. With thicker materials, the straightener is responsible for pulling material off of the coil as the decoiler mandrel spins with slight resistance from the pneumatic brake to create small tension in the strip. The thinner materials typically straightened for EV lines are so thin, the material may tear due to tension on the strip between the straightener and decoiler. The powered payoff motor feature on the decoiler prevents tension on the strip, enabling the material to be fed at the same speed as the straightener without tearing. The powered payoff motor is only one of the features incorporated to meet the needs of lines processing EV material. Other features are also discussed on this page.

Optional Features

EV Precision Straighteners

- Speed Control Package – provides stable, accurate loop control when straightener is feeding material into a loop

- Motorized Entry & Exit Adjustment – incorporates push button control of entry and exit roll position

- High Speed Option – provides an increase in speed to 4000 inches/minute without loss of machine performance or capability

- Powered Pinch Rolls – aids in threading of material into the straightener and extends the life of the work rolls

- Powered Pull Rolls – poly-coated rolls with an independent motor located at the exit end of the straightener that adds tension to the strip to obtain more material in yield

- Chrome Work Rolls – helps reduce material pickup and marking of the rolls

- End of Strip Sensor – indicates presence of strip and turns off the ready to run signal to the press when strip is not present

- Bolster Extension Kart with Arms – aids in the installation and removal of the cassette

- Single Arm Decoiler Controls – integrates Forward/Reverse, Mandrel Expand/Collapse, Hydraulic Pump Start/Stop controls on the main operator panel

- Double Arm Decoiler Controls

- Coil Car Controls

- Additional Auxiliary Decoiler Station Control – integrated into a remote pedestal to assist in unloading a coil from the backside of the decoiler

- Press Interface Quick Disconnects

- Decoiler Interface Quick Disconnects

- Common Mounting Base – for assembling and mounting s-loop straightener and decoiler