Explore our product gallery of innovative metal processing equipment and custom machinery engineered and built by our team for some of the most demanding manufacturing environments.

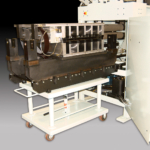

Coil Processing Shears

Pinch roll and shear combinations

Press Room Equipment Shears

One of the fastest non-servo driven shears in the industry

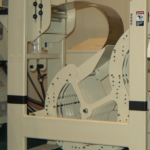

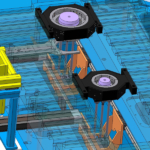

Bridle Rolls & Tension Stands

Self-threading and entry bridle rolls; tension and deflector roll stands

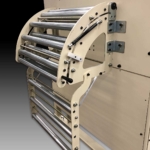

Coil Processing Flatteners

3-, 4- and 5-roll flatteners for both over winding and under winding

Press Room Equipment Flatteners

A cost competitive option for removing coil set defects

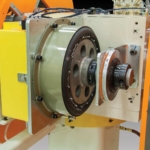

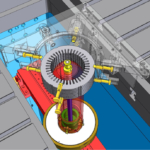

Mandrels

Design, build and install of unwind mandrels

Belt Wrappers

Endless belt designs available

Coil Processing Stackers

Custom equipment designs and controls for integration into existing lines

Press Room Equipment Stacking Systems

Delivers mobility and manageability, all while maintaining the highest level of performance possible

Custom Equipment

Custom design and build solutions for coil processing

Slitters

High precision, high speed, slitting and trimming applications

Side Trimmers

Side trimmers for applications in mills, cut to length lines and high-speed finishing lines

Scrap Choppers

Custom-designed scrap choppers to accommodate slitting and side trimming scrap handling needs

Specialty Process Lines

Specialty processing equipment for the steel, aluminum and specialty metal industries

Coil Cars

Designed with operator safety and coil stability in mind

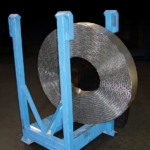

Coil Cars & Coil Stands

Designed to improve coil line efficiency by creating a safe and quick coil loading system

Upenders and Downlayers

Specialized designs for large diameter coils

Roller Cutter Knives

Versatile handheld roller cutter knives for efficient cutting and trimming of light to medium gauge sheet product

Decoiler

Superior coil handling control for a wide range of light to heavy duty loads

Looping Systems

Used to present the strip to the feeder without putting coil set back into the material

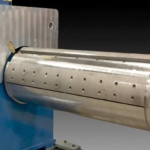

Precision Roll Services

New work rolls, intermediate rolls and repair/reconditioning services for multi-roll levelers, tension levelers and straighteners

G2 Precision Straighteners

Designed for lighter gauges and normally higher speed applications

H2 Precision Straighteners

Designed for heavier gauges and normally slower speed applications

EV Straighteners

Designed for lighter gauges and normally higher speed applications

Precision Part Straighteners

Designed to obtain a level of flatness and speed that many other parts straighteners cannot achieve

Rewinders

Gain efficiencies with a gripping mandrel rewinder or belt wrapping rewinder

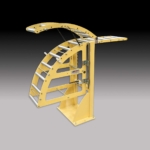

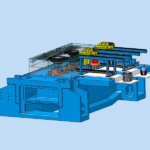

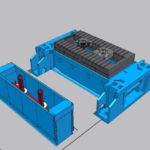

Above Bed Stacking (ABS)

Receive stamped laminations above the press bed and present them to the operator on the side of the press

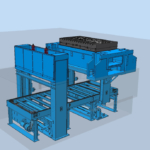

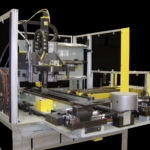

Automatic Press Load/Unload Stacking

Increase pressroom production while at the same time creating an efficient, operator safe work place

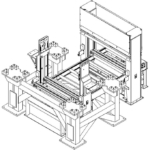

Below Bed Stacking

Receive stamped laminations below the press and present them to the operator at floor level

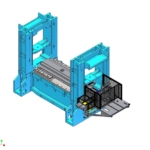

Die Ejection Stacking

Designed to catch and remove parts being ejected from the upper die

End of Crop Stacking

An end cut operation that allows the stacker to catch the lamination as it is being cropped from the end of the die

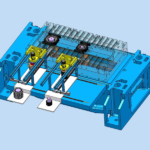

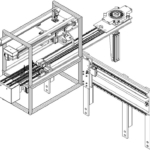

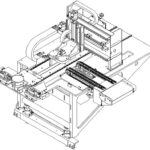

Scroll Lines

A creative way to scroll slitting lamination material of circular or hexagonal parts

Parts Retrieval System

A reliable, cost-effective way of removing parts and scrap from the die