Machine Concepts has extensive experience rebuilding all types of equipment with special expertise in Slitters, Side Trimmers and Scrap Choppers. We offer complete line rebuild and upgrade services to suit our customer’s needs. When required, we can supply custom engineered solutions and upgrades for many applications. Our basic rebuild scope of work includes the following:

- On-site baseline inspection

- Complete equipment inspection and reports before teardown, including endplay checks, breakaway torques, run-out checks, etc. – all reports are provided to the customer for their records

- “Pre-Rebuild” inspection reports according to print specifications, including arbor measurements and run-outs, housing bore measurements and bore alignments

- Final inspection reports and run-in data provided to customer

- Multiple upgrade options including new drives (retrofit into existing heads), new fixed or set-up bases, high precision bearings and improved arbor precision

- Slitter arbor upgrades to accept hydraulic hub cutters, knife holders or specialized tooling

- In-house inspection of precision bearings and grinding of bearing spacers for proper preload or endplay – Machine Concepts has experience setting up bearings up to 40” diameter

Coil Processing

Machine Concepts can rebuild and upgrade your specific brand and model of coil processing equipment.

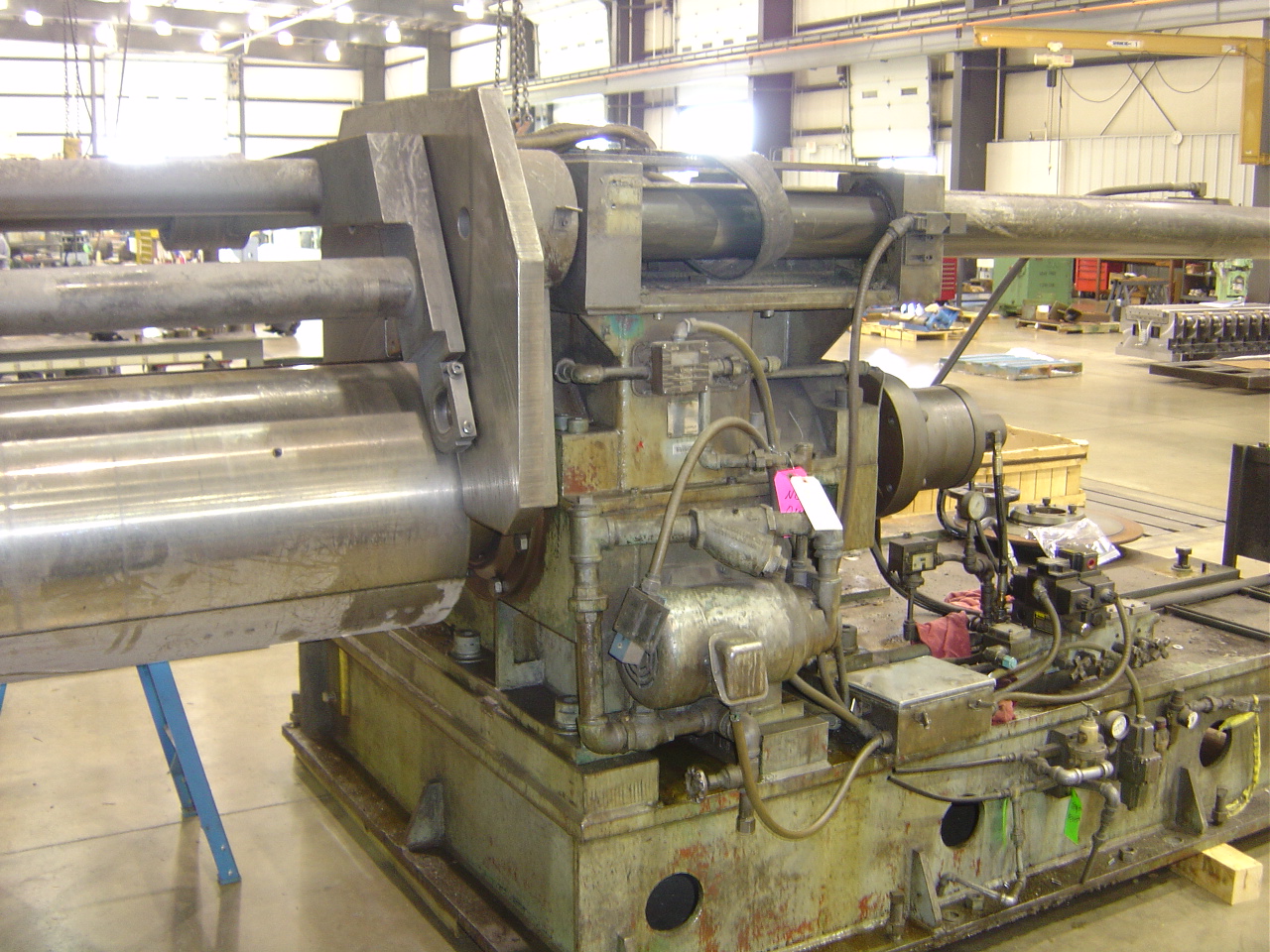

As received

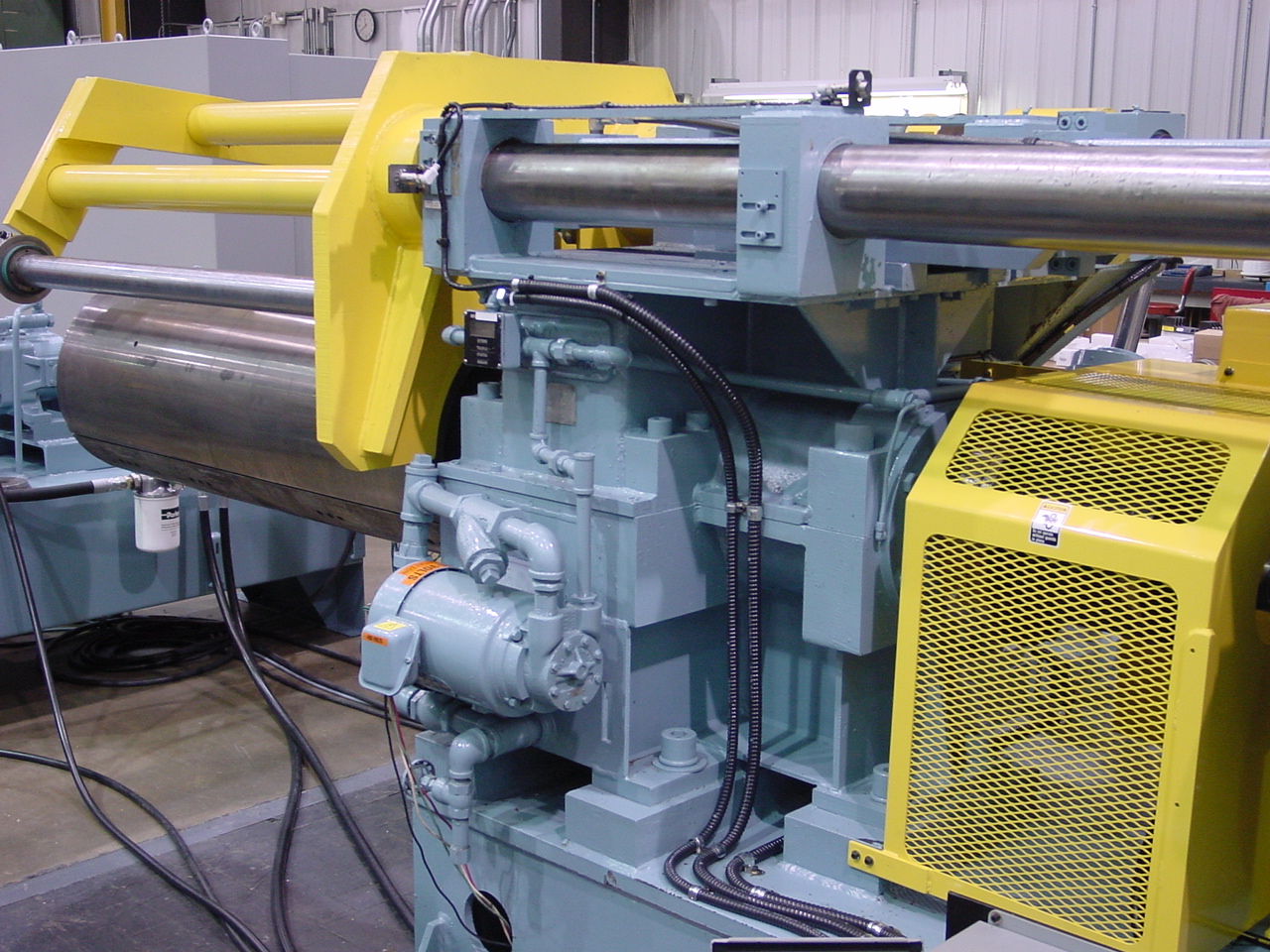

Rebuilt and Upgraded

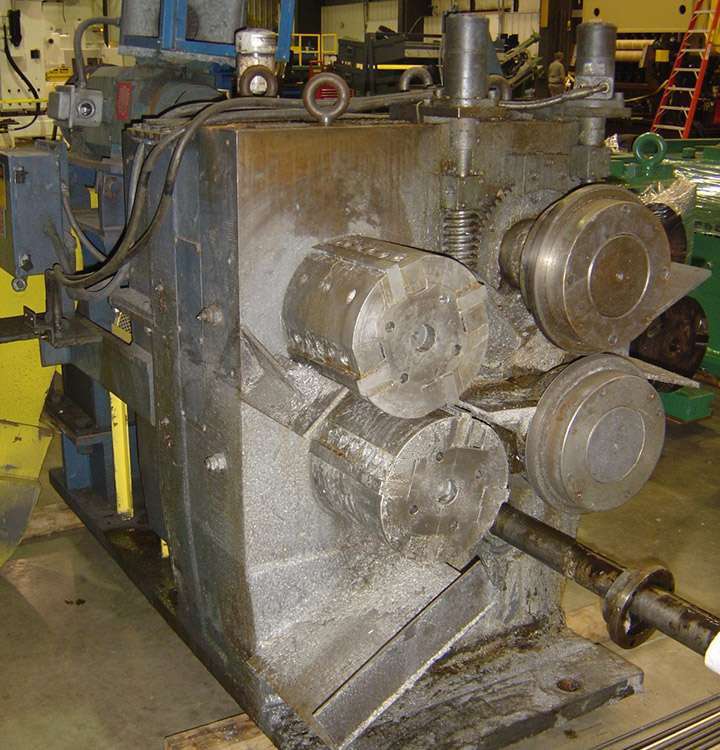

Hot Mill Trimmer / Choppers

Machine Concepts has rebuilt many Hot Mill Trimmer / Choppers for several different companies. Rebuild procedure consists of the following:

- Full inspection (as received) to check trimmer arbor run-outs, bearing and sleeve endplay checks and breakaway torques on chopper set-up

- Complete teardown, including disassembly down to bare arbors and housing

- Set up arbors and housing on a machine and fully inspect diameters and bore alignments according to print specification

- Clean all reusable parts and paint where applicable

- Reassemble arbors and put back into housing

- Set up chopper knives for proper clearances and heights

- Final inspection of endplays, arbor run-outs and breakaway torques

- Continuous test run to seat in bearings and assure proper running ability when put back into the line

- All inspection and run-in data to be given to customer for their records

Before

After

Scrap Choppers Rebuilds and Upgrades

Machine Concepts has extensive experience rebuilding all types of scrap choppers. When required, we can offer engineered solutions to upgrade or retrofit existing machines. Our basic rebuild scope of work includes the following:

- On-site baseline inspection

- Complete equipment inspection and reports before teardown, including endplay checks, breakaway torques, knife heights and gaps and arbor lift (all reports are provided to the customer for their records)

- “Pre-Rebuild” inspection reports according to print specifications, including arbor measurements and run-outs, housing bore measurements and bore alignments

- Refurbish and repair work per customer’s instructions

- In-house inspection of precision bearing and grinding of bearing spacers for proper preload or endplay to obtain knife gaps required for high quality trimming and chopping (Machine Concepts has experience setting up bearings up to 40” in diameter)

- Reassembly with new bearings and seals

- Chopper set-up with proper knife height and gap. Anti-backlash gearing spacers are measured and ground to control chopper knife gap during operation

- Lengthy test runs on chopper heads before shipment

- Final inspection reports and run-in data provided to customer

Before

After

Side Trimmers Rebuilds and Upgrades

Machine Concepts rebuilds all brands and models of Side Trimmers besides our own, including Trimmers that fall into the following categories:

- High speed precision trimmers running from 1000 to 6000 fpm – cutting .003 to .040 aluminum or steel

- Medium to Heavy gauge trimmers cutting .040 to .375 aluminum or steel

- Pickle Line trimmers with a wide range of speeds, material and gauges (We have rebuilt many Wean style PL side trimmers for various companies)

- Hot Mill trimmers with a gauge range of .080 to .400

Rebuild and Retrofit Options for Side Trimmers

- Add horizontal knife adjustment – motorized or manual

- Add vertical trimmer knife adjustment – motorized or manual

- Add digital displays for horizontal and/or vertical knife adjustment

- Add knife width gauge with digital display for simple operation

- Arbor replacement or modification to establish Fixed Knife Cutting Edges, to reduce set-up time and create set-up consistency

- Scrap handling and scrap chute modifications

- Custom electrical upgrades, drive upgrades and automation

- Bearing replacement or modification to improve accuracy, reduce running temperatures, extend running life and reduce maintenance requirements

Digital Displays

- Horizontal gap, vertical gap and cutting width

Before

After

Slitters

Machine Concepts rebuilds many different brands and models of Slitters besides our own, to meet our customer’s needs. We specialize in high precision slitters that run at very high speeds and slit the thinnest of material, and we also rebuild heavy gauge Slitters of all types. Rebuild procedure consists of the following:

- Full, as received, inspection checking Slitter arbor run-outs, bearing and sleeve endplay checks, arbor parallelism throughout cutting range and arbor drop, which will show any excessive clearances inside the housing

- Complete teardown: disassembling down to bare arbors and housing

- Set up arbors and housing on a machine and fully inspect diameters and bore alignments according to print specification

- Clean all reusable parts and paint where applicable

- Reassemble arbors and sleeves with new bearings and put back into housing

- Final inspection of endplays, arbor run-outs and arbor parallelism

- Test run for a continuous run, to seat in bearings and assure proper running ability when put back into the line

- All inspection and run-in data to be given to customer for their records

Before

After