Machine Concepts specializes in the integration of air bearing shape roll technology to provide superior shape measurement and strip flatness.

Machine Concepts continually develops and implements air bearing shape roll technology to respond to increasing mill speeds, changing properties of metal and increasing demands for improved quality of strip flatness.

Our core shape roll capabilities and services include:

- Mill engineering services and in-house manufacturing to meet process requirements

- Shape roll components/equipment – new and repair:

- Air bearing shape roll assemblies

- Transducer cabinets

- Retract mechanisms

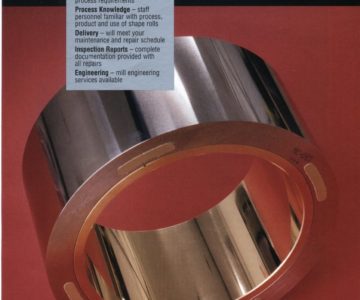

- Rotors (including chrome outside diameter)

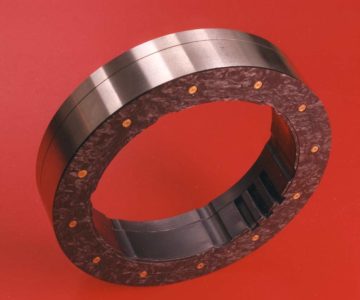

- Thrust bearings

- Field service, on-site rebuilds and repairs

- Reasonably priced shape roll replacement parts

Why Choose Machine Concepts

- Turnkey services including engineering, manufacturing and repair

- Extensive experience – we have been integrating shape roll technology since 1994 and each team member has over 18 years of experience

- Responsive to mill maintenance, repair and delivery schedules

- Utilize high-precision equipment dedicated solely to air bearing equipment manufacture and repair:

- (2) ID Grinders

- (1) OD Grinder

- (1) Rotary Grinder

- Provide complete inspection reports and documentation for all repairs

- Pioneered the manufacture and repair of rotors with chrome coatings – advantages include wear life, surface finish, corrosion inhibitor and elimination of “pick-up” on outside diameter of rotor

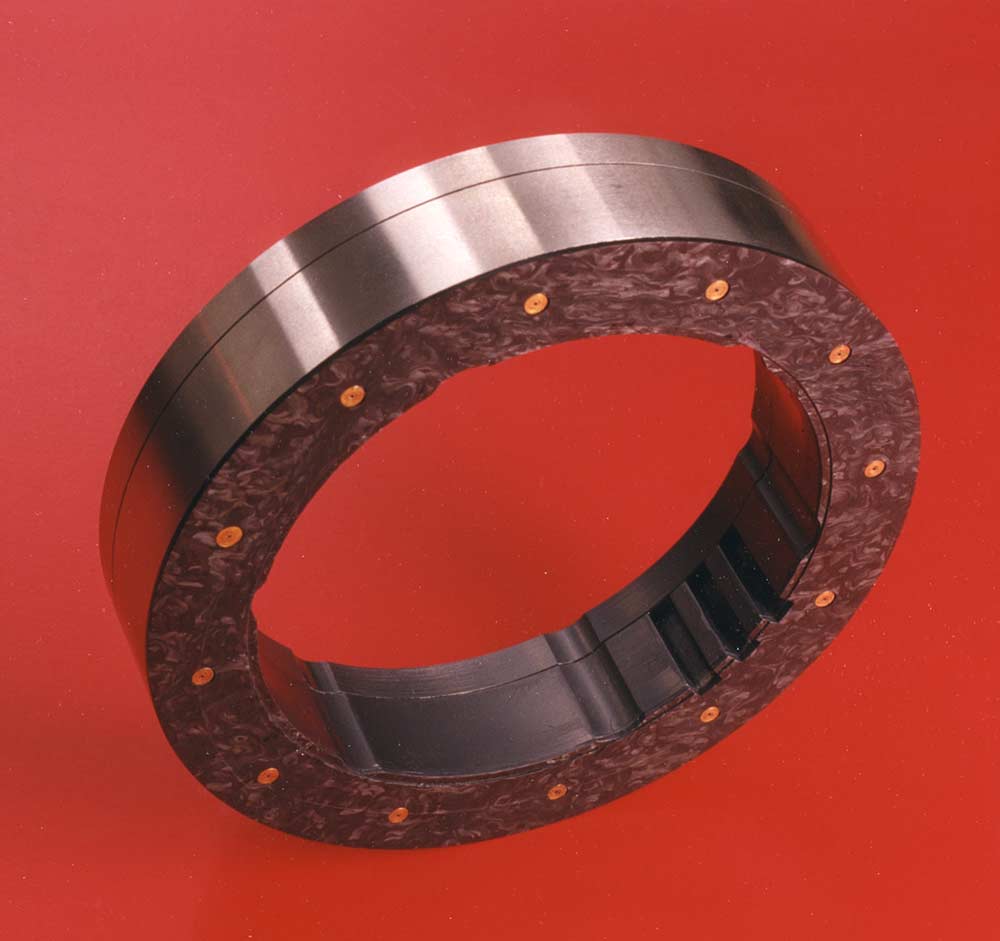

- Pioneered the use of wear resistant Hy-Comp composite material for rotor face pads and thrust bearing face disks – exclusive to Machine Concepts

- Committed to listening and responding to our customers’ needs

Thrust bearing featuring our exclusive wear resistant Hy-Comp composite material

Testing and Inspection

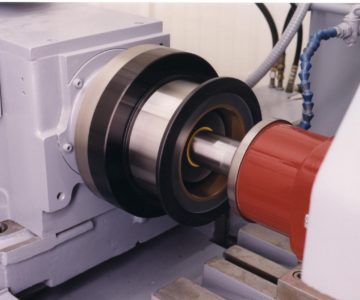

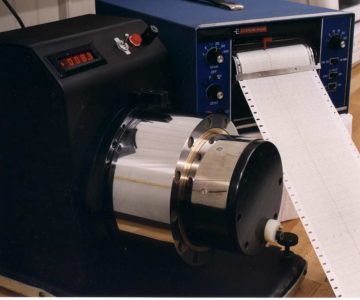

The output signal of all rotors is measured before and after repairs on a Test Stub, Machine Concepts’ proprietary test fixture. These measurements quantify each rotor’s performance characteristics and are used to meet exact manufacturing dimensions. Complete inspection reports are provided to the customer with all repairs.

Test fixture

Standard Features

- Measurement width: 2” to 4”

- Continuous measurements per revolution that are independent of mill speed allowing for output as fast as control system can process signal

- Excellent accuracy at low and high speed measurements

- Low inertia and friction loss – drive motor not required

- Measures tension

- Very high sensitivity

- Simple design and low complexity

- Small installation envelope for confined spaces

- Remote transducer cabinet

- Houses electronics for easy access and maintenance

- Provides protection from mill environment

- Enables roll to stay in mill and remain running while performing transducer maintenance or replacement

- Hard chrome on outside diameter of the rotor (superior to flash chrome)

- CNC ground edge radius on outside diameter of the rotor

Optional Features

- 1” measurement width resolution

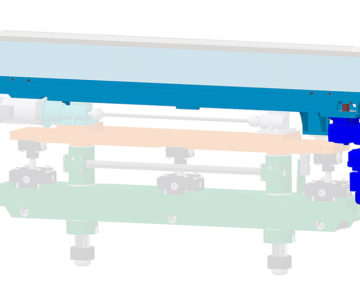

- Infinite variable height retract mechanism

- Skewing device

- Thrust sensing feedback

- Hy-Comp material used on rotor thrust pads and thrust bearings

- Specified materials and procedures used for high temp applications

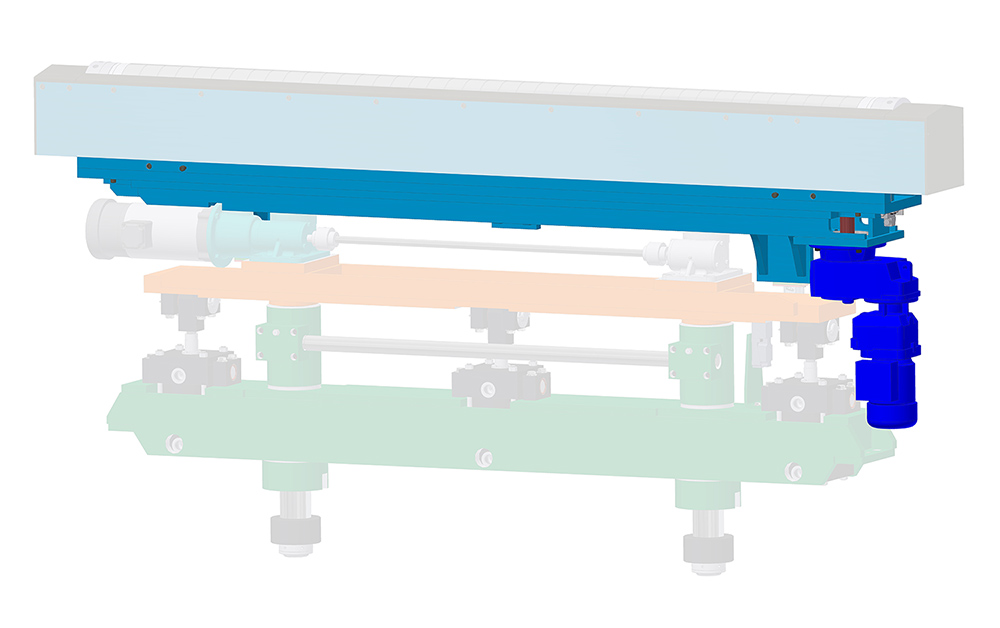

Infinite variable height retract mechanism (picture above)

The infinite variable height retract mechanism is equipped with a variable motor and machine screw jacks for adjusting the position of the shape meter assembly and hence the load on the rotors. The load control from the automation sets the height of the shape meter assembly based on the average rotor load into the pass-line of the strip while limiting the maximum rotor load. This gives maximum resolution possible for any strip thickness and metal properties.

Skewing device – illustration above (in blue)

The skewing device adjusts laterally to keep the strip perpendicular to the roll. The gear reducer motor is controlled by the mill automation through a signal from the thrust sensing bearings on each end of the rotor stack. This can be very beneficial for mills that have dual rewinds that are not exactly parallel, or a rewind that starts to droop from the weight of the coil.