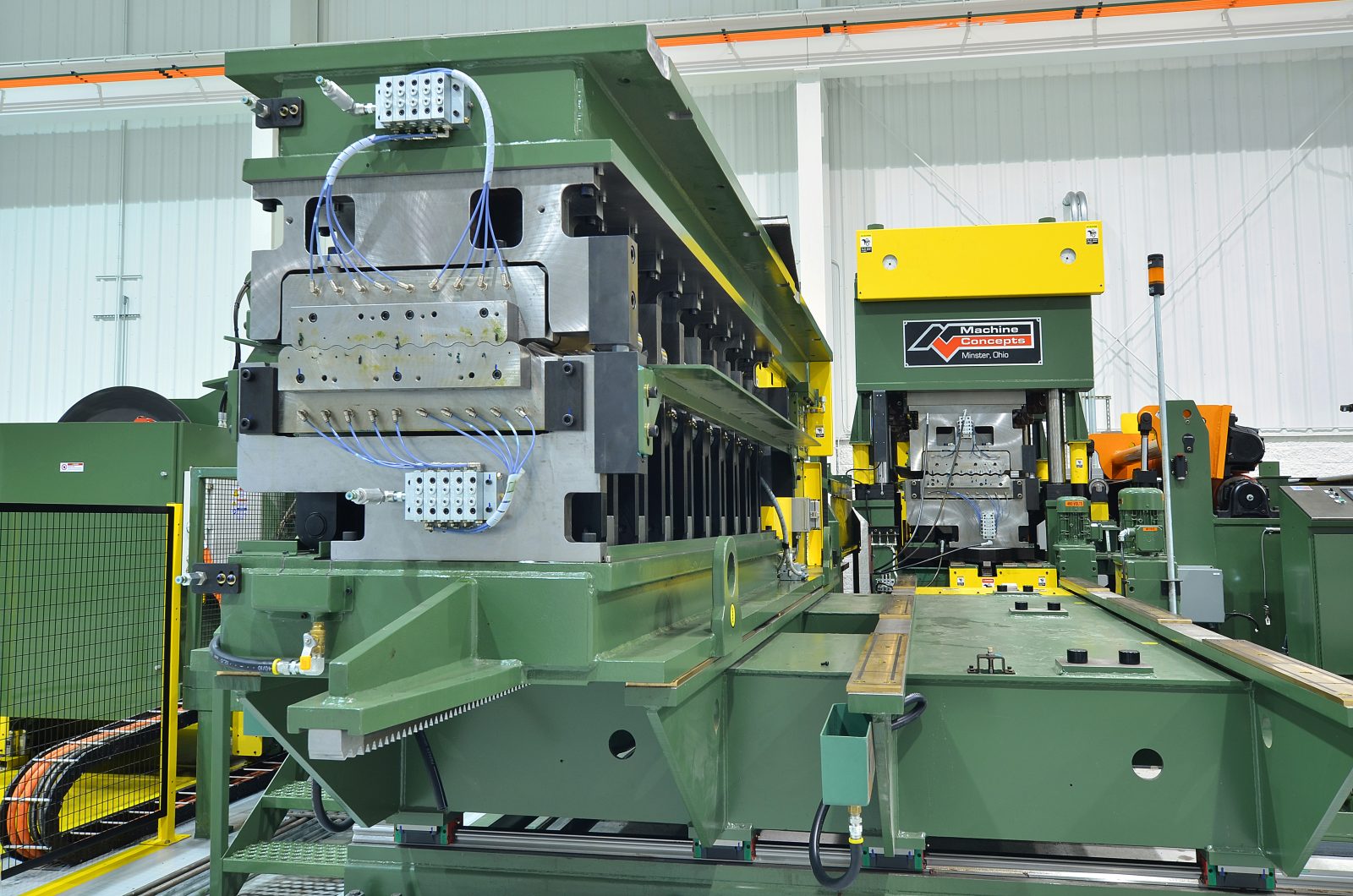

The G3DC leveler provides the ability to easily remove the entire cassette for cleaning, service, exchange, etc. The G3DC requires either a docking station or exchange system to remove the cassette.

Features

- Automatic self-calibration after roll grind or parts replacement

- Automatic setup based on material parameters

- Floating journals reduce journal bearing load for longer life and better roll bend control

- Overload protection via drive load monitoring and hydraulic relief

- Automatic journal bearing lube system

- Removable roll cassette for cleaning or changing work rolls. Different diameter cassettes can be exchanged to expand leveler gauge range

- Work roll modules can be quickly removed as sub-assembly for cleaning and service

Frame and Roll Sizes

- Frame sizes: 80,000 lb. up to 1,200,000 lb. separating load

- Widths: 48” to 96”

- Roll sizes: 0.875”, 1.3”, 1.5”, 1.75”, 2.25”, 3”, 4”, 5”, 6.5”

- Typical max gauge: Approximately .750” for largest roll size depending on material width and yield strength

Available Drive Systems

- Pull thru for coil to coil lines

- Pull thru with pull roll after leveler for very light gauge CTL applications

- Upper roll assist drive for either coil to coil lines or used with optional pull roll

- All rolls driven via separate upper and lower pinion boxes and drive shafts

- Split cluster drive system compensates for differential roll speed and reduced drive stress

Optional Features

- Cassette exchange system or a docking station to receive and store cassettes

- Off-line lifting bale and upper cassette rotator for easy cleaning and service of cassette

- Patented roll cleaning process to quickly and easily scrub work rolls between coils

- Lateral tilt to compensate for differences in material properties from edge to edge

- AutoFlat® automatic shape control system

- Job and product recipe storage