Machine Concepts designs and builds a wide range of coil processing terminal equipment. We have extensive experience in both mill and service center applications. We can provide high-quality engineered solutions for the most demanding requirements.

Machine Concepts builds a full line of coilers with many different capabilities and features.

Common Features:

- Fixed bases or lateral adjust capability

- Edge guiding or center guiding systems

- Integrated hold down arms

- Complete separator arbor assemblies and tooling packages

- Paper or PVC interleafing equipment

- Several styles of outboard bearings available

- Roll configurations to suit any line layout or application

- Sliding journal block or pivoting frame designs

- Electric or hydraulic drive systems

- Many roll and roll covering options available:

- Standard polyurethane or nitrile

- Hardened steel

- Custom spray weld coatings

- High-temperature rubber covering

- Nonwoven compressed fiber

- Special applications based on customers’ needs

Pinch roll and shear combinations are one of Machine Concepts’ standard machine packages. Dual peeler table or strip feed options are also available.

Crop Shears

- Hydraulic and mechanical designs available

- Single rake or double rake cutter bars

- Up or down-cut capabilities

- Simple compact designs allow retrofit into existing lines

- Heavy-duty welded steel construction

- Squaring shears for strip welder applications

Flying Shears

- Hydraulic and mechanical designs available

- Hydraulic or servo line speed matching controls, custom for your application

- Adjustable knife gap options available

- Complete controls packages as requested by our customers

Zip Shears

- Compact zip shears can be installed in many areas with limited space

Drum Shears

Rotary Shears

Self-Threading Bridle

- Two plunge rolls create easy threading of the line

- Tension amplification of 5:1 is possible

- Load cells are incorporated for accurate tension readout

- Rolls are quickly opened to reduce threading time

- Bridle roll stands are driven by means of variable speed AC motors and helical gearboxes.

Entry bridle roll

- With threading table and exit load cell to allow the operator to quickly thread the material as well as give accurate tension read-outs to the operator

Tension stands

- Heavy-duty design with a custom drive system to suit your application

- Also include integrated tension measurement capabilities

Deflector roll stands

- We offer 3, 4, and 5 roll flatteners for both over winding and under winding to suit customer applications

- Hydraulic threading drive options for pull-thru applications. Also, offer all rolls driven via external pinion stands for full line speed capability

- Hydraulic or electric roll positioning. Closed-loop roll position controls available with a custom operator display panel and automatic setup options available

- Multiple roll types and surfaces available for standard and special applications

- Optional pinch roll or entry equipment combinations available to suit your application

- Stand-alone electrical control cabinets and dedicated hydraulic power units can be supplied for a self-contained, fully functioning system

- Machines designed for quick roll change capability to decrease downtime and maintenance

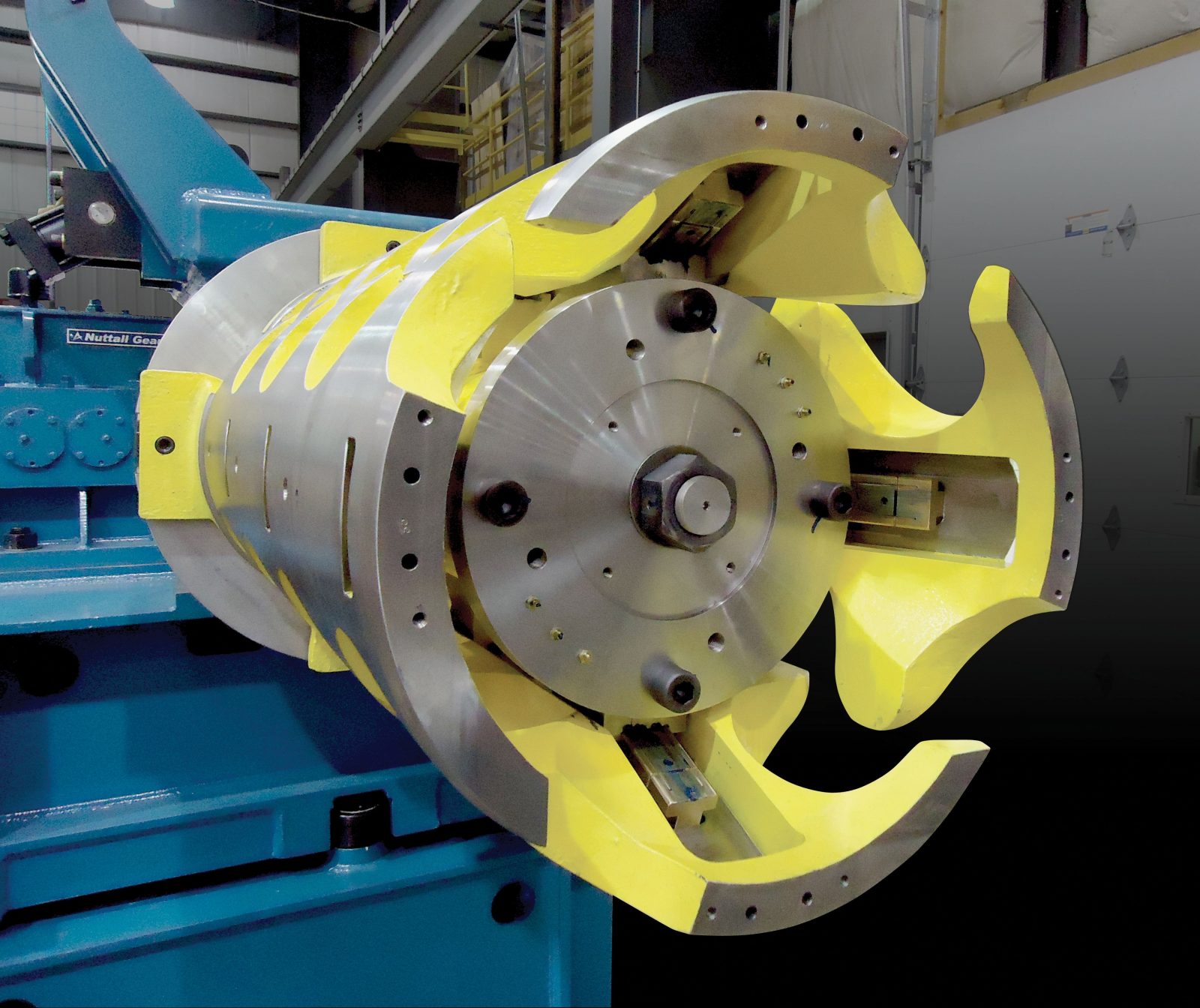

Machine Concepts designs and builds several types of unwind mandrels to fit your application needs. We also source and install custom rewind mandrels as required.

- Barrel type design with one piece expand wedge

- All wear surfaces are manufactured from solid bronze or aluminum bronze

- Cast iron segments with interlocking serpentine edges to prevent coils from getting under segments

- Large expand ranges – custom expand ranges and face lengths upon request

- Several outboard bearing nose options available

- Heavy-duty welded steel construction throughout

- Configurations for overwinding or underwinding

- Automatic hydraulic or pneumatic belt tensioning

- Many rubber and/or steel belting options

- Custom designs to match existing line layouts

- Endless belt designs available

- Drop or air float systems available for ferrous and nonferrous applications

- Custom end stops with many adjustments and shock absorbing options

- Chain-type side conveyors

- Driven roller conveyors

- Custom scissors lifts

- Weigh scale systems

- Custom equipment designs and controls for integration into existing lines

- Multiple options available

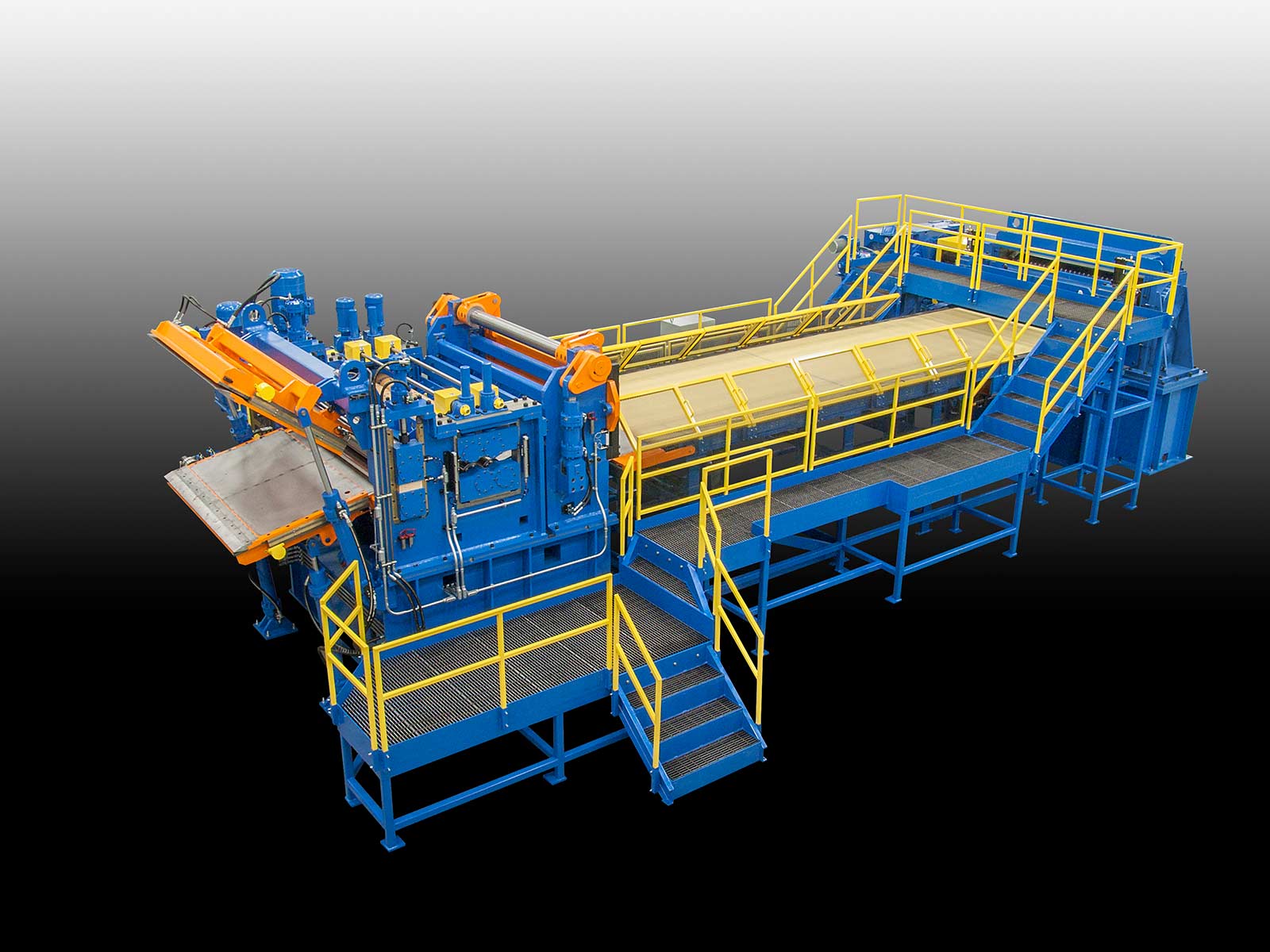

- Manual Visual Inspection

- Digital Surface Inspection

- Integrated flattener and crop shear

- A variety of inspection conveyor options available, such as urethane belts and hi-temp belts

- Full-width chopper available for disposing of inspected sheet

Integrated coil size measuring and weighing options available.