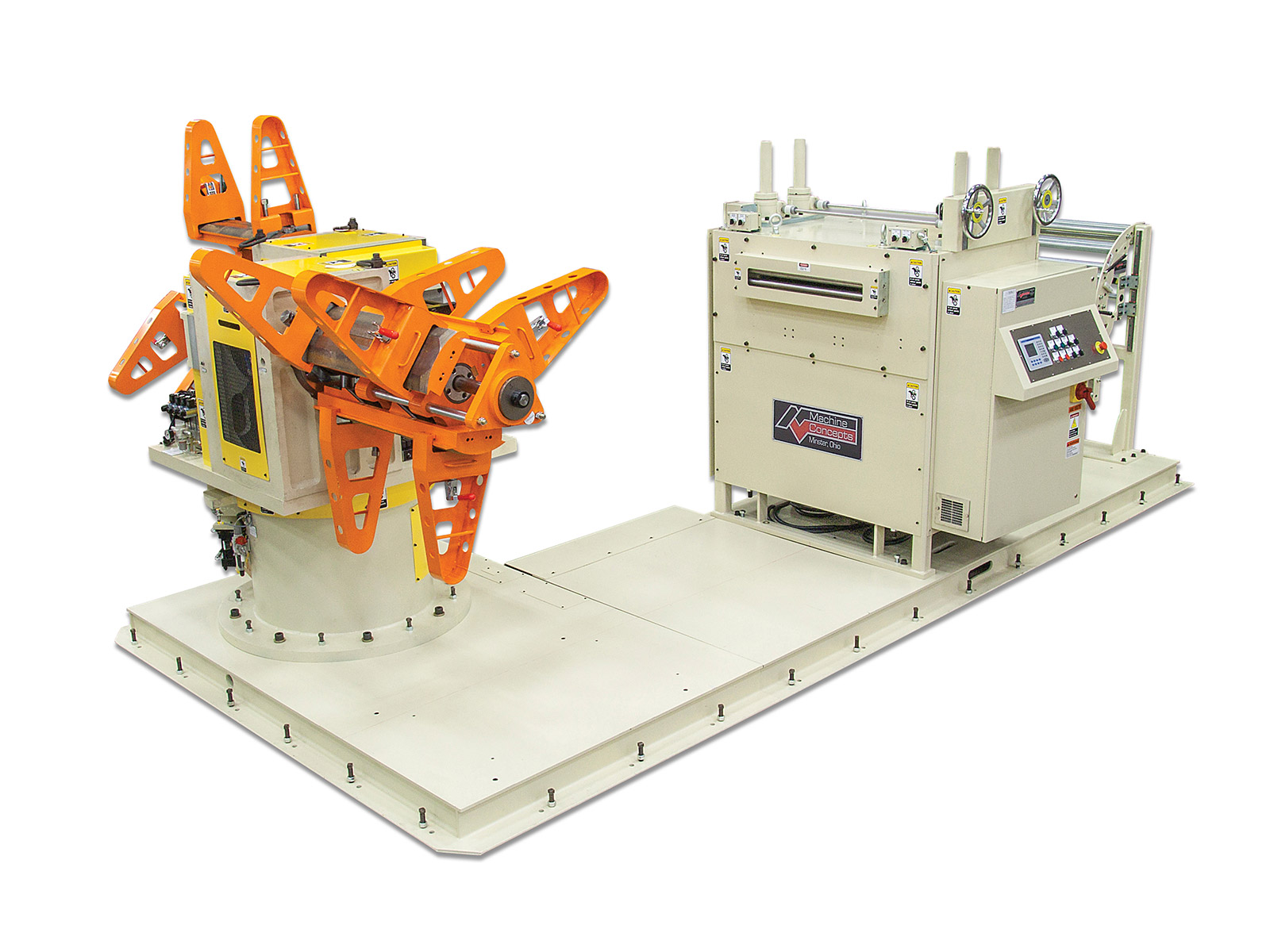

The G2, G2 Plus & G2L family of straighteners have been designed for lighter gauges (.005” to .100”) and normally higher speed applications (100 to 400 FPM). Features include easy,…

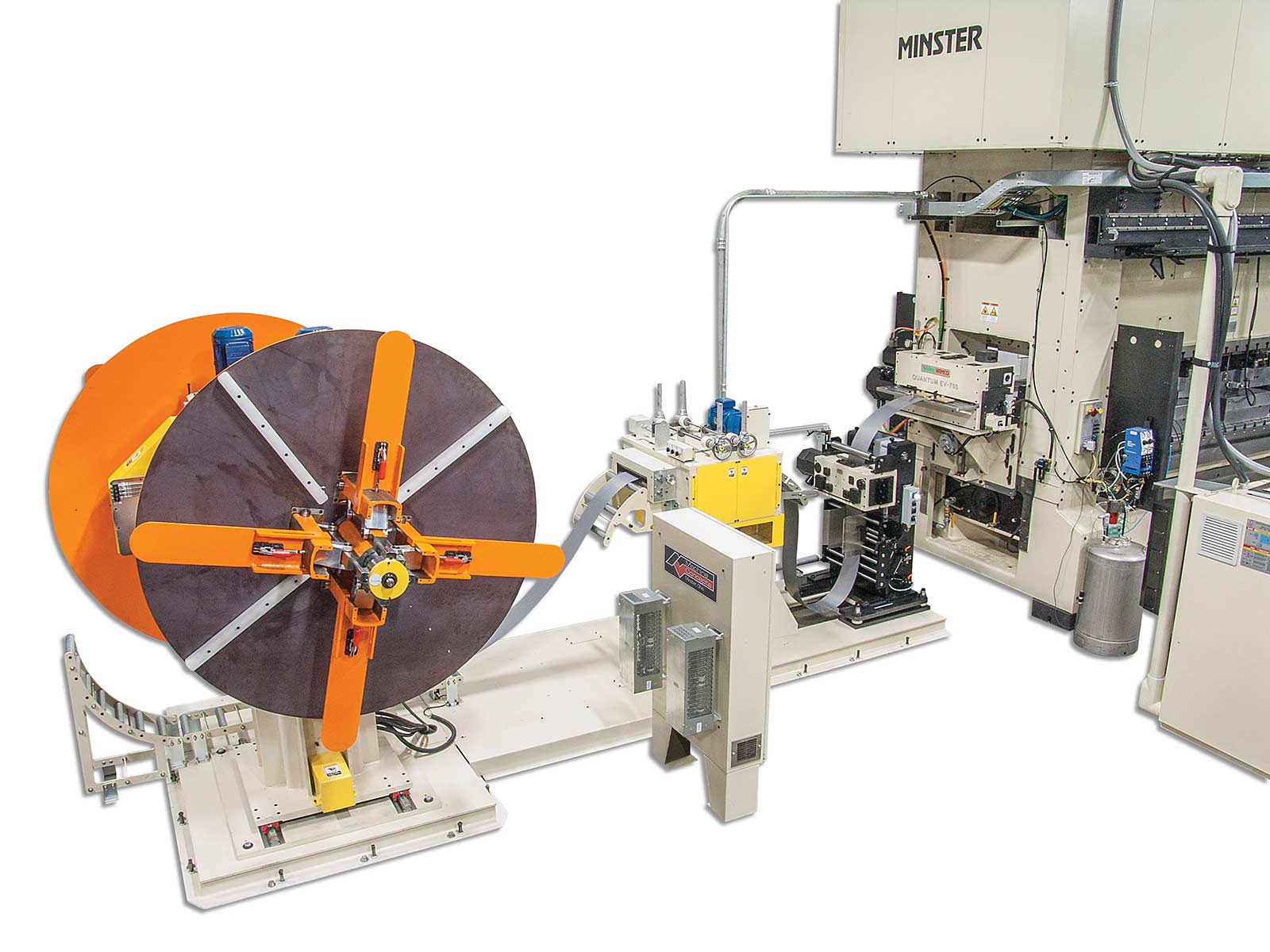

H2 and H2L family of straighteners have been designed for heavier gauges (.020” to .500”) and normally slower speed applications (30 to 200 FPM). Its ability to remove coil set…

H2 and H2L family of straighteners have been designed for heavier gauges (.020” to .500”) and normally slower speed applications (30 to 200 FPM). Its ability to remove coil set…

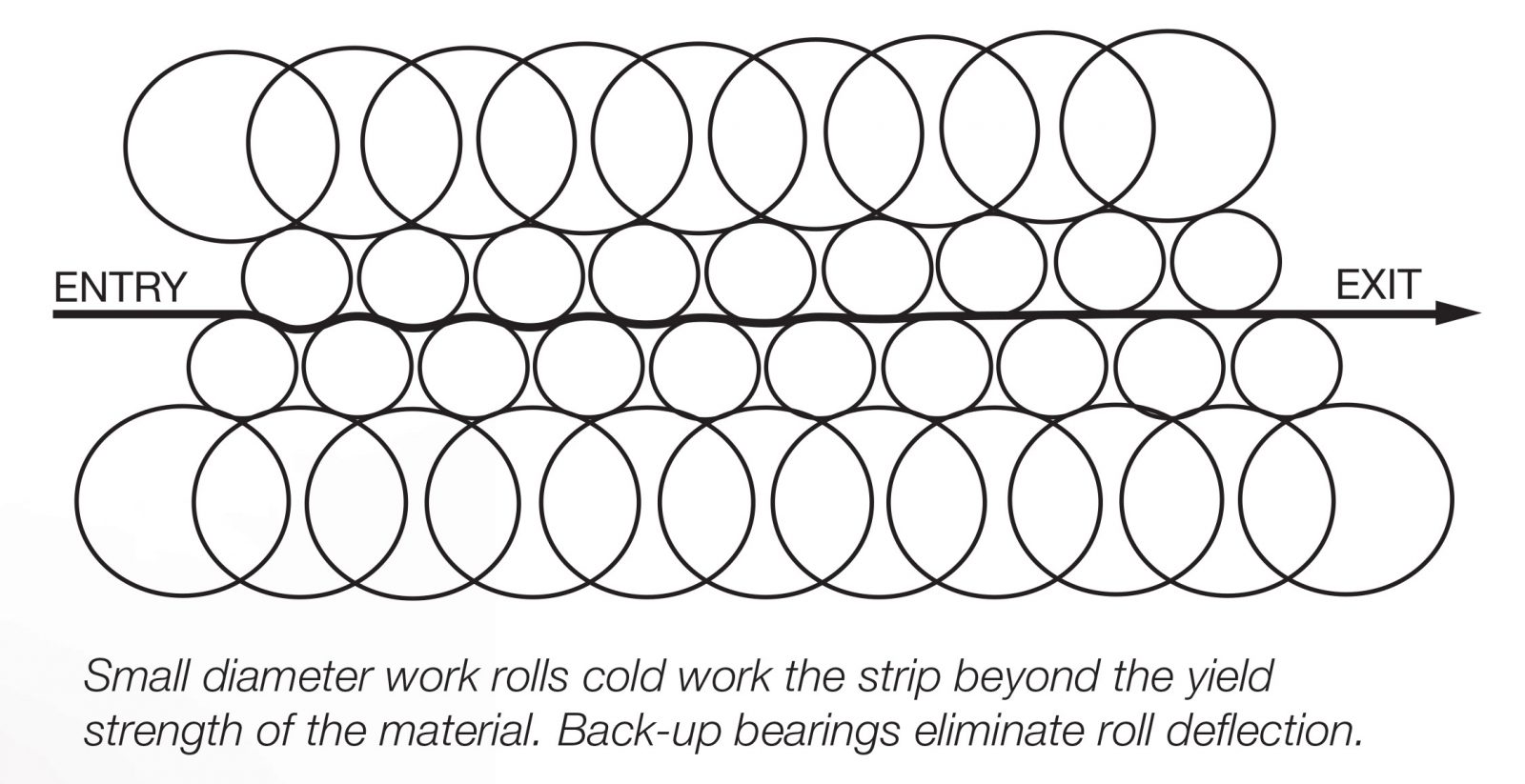

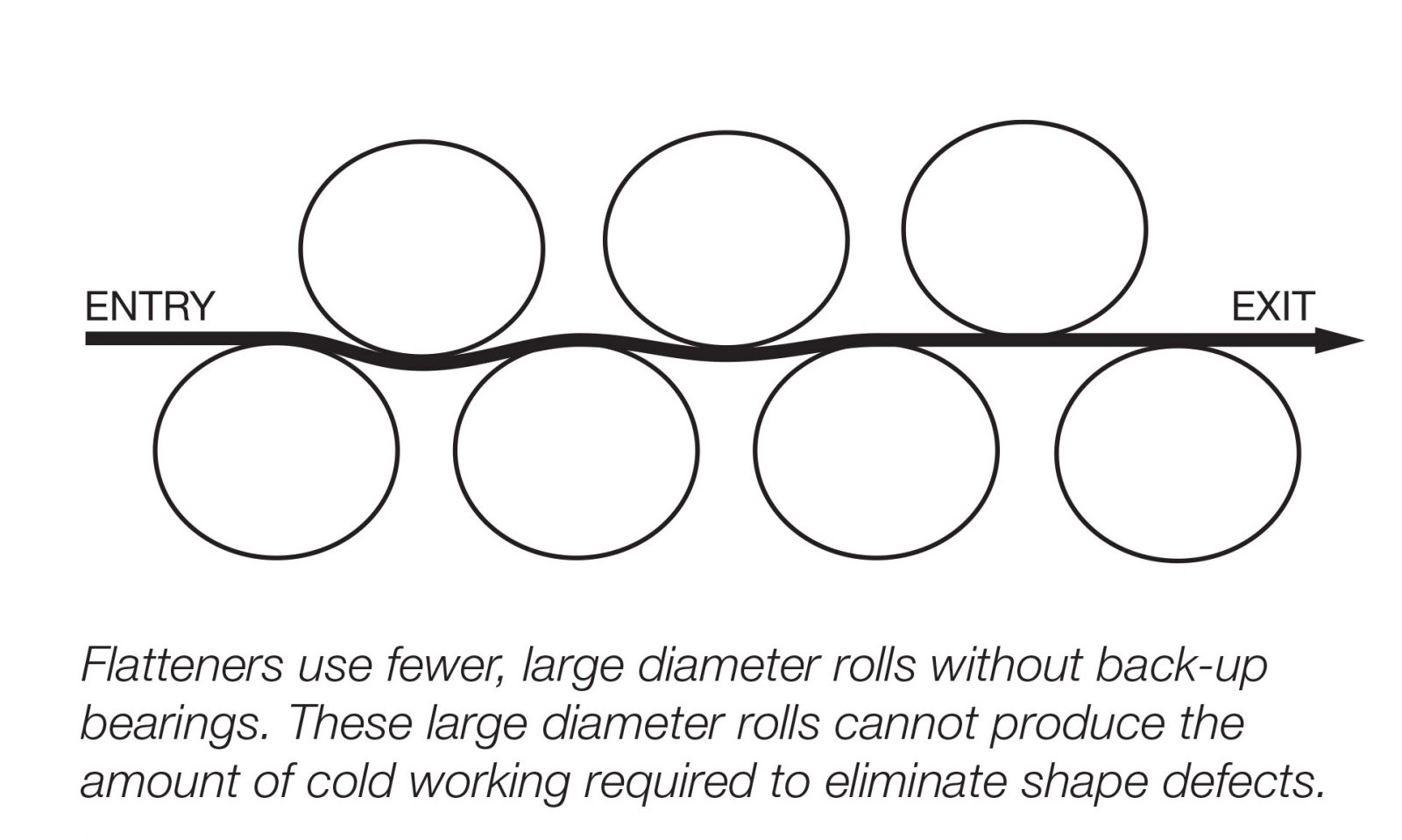

Precision straighteners eliminate coil shape defects that simple flatteners cannot remove. Small diameter work rolls with supporting back-up rollers produce a flat strip free of stress. Parts that need to be flat stay flat and round parts stay round.

- Family of frame sizes and roll diameters to cover a large range of materials

- Interchangeable roll diameter cassettes within the same frame size

- Removable cassette and modular designs provide fast and easy roll exchange, cleaning, inspection and maintenance. L2/EV requires more manual operation to change the cassette.

- Precision ball and socket set to align top and bottom roll banks for accurate alignment

- Hardened and precision ground work rolls supported with double row needle bearings

- Durable roll drive system eliminates problems of U-joints and enhances straightener capabilities in several ways

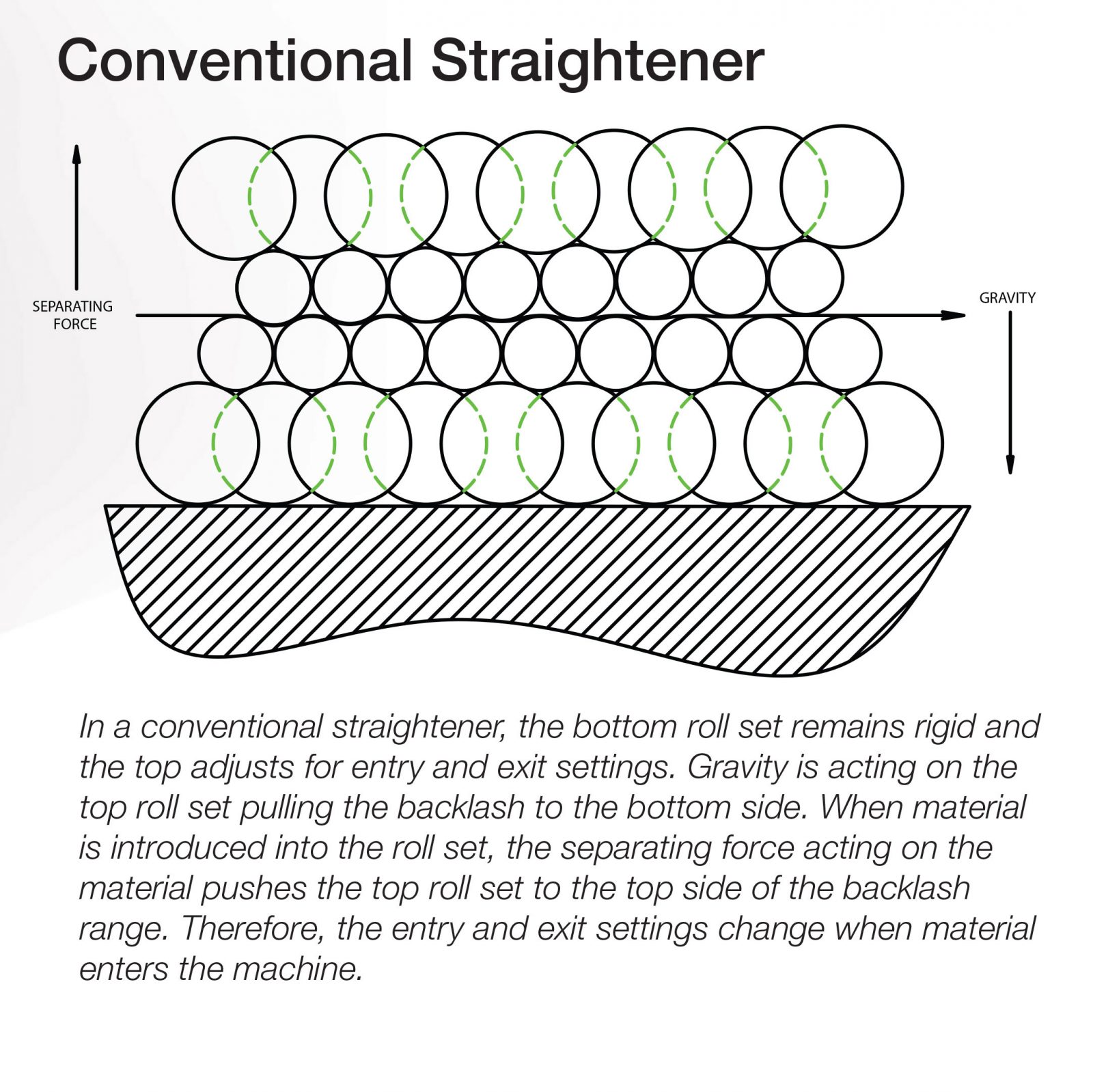

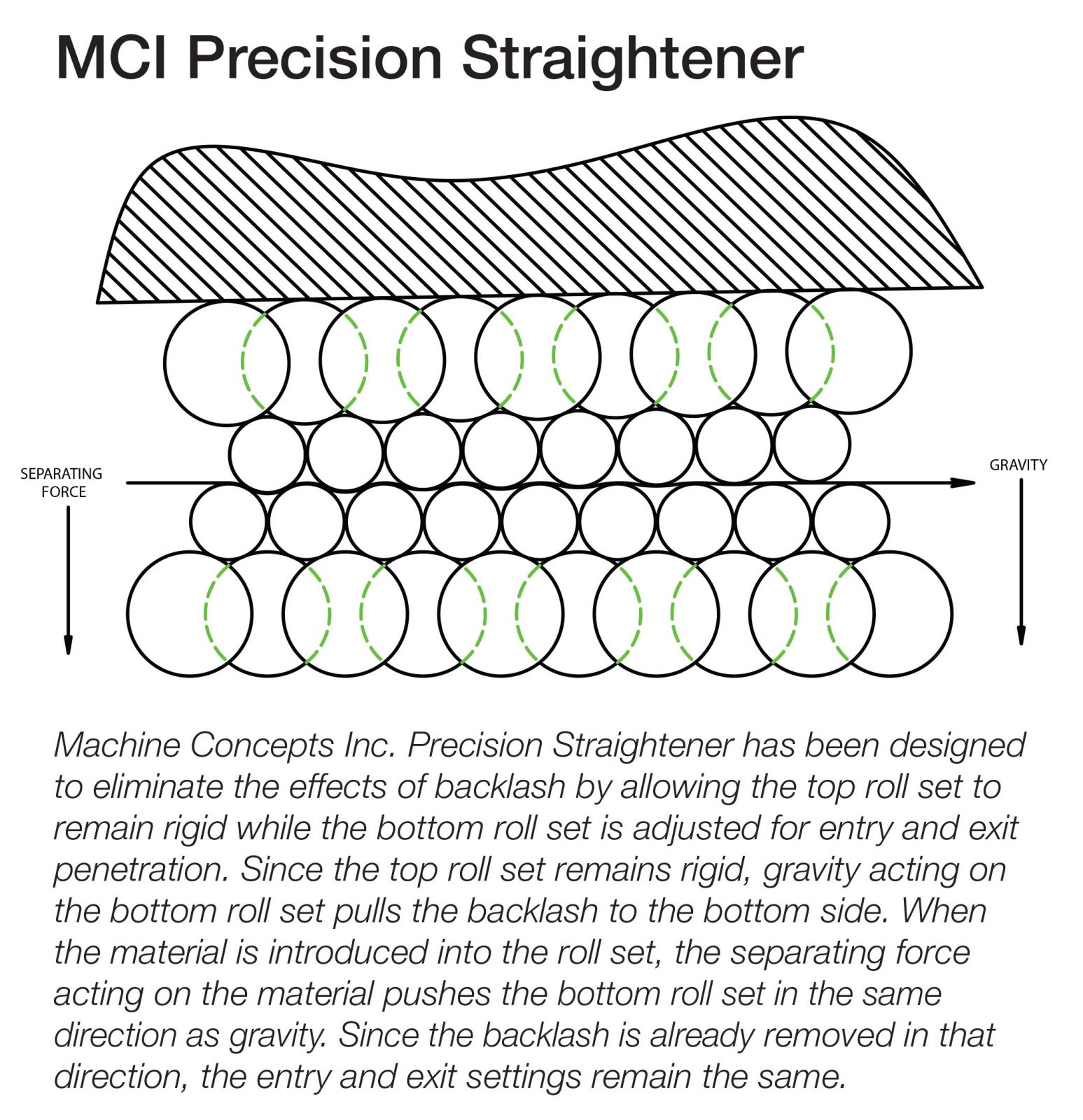

- Hanging cassette design eliminates adjustment backlash and greatly reduces machine deflection

- Continuous light oil lubrication with flow and level monitoring

- All electrical drives, controls and panels are machine mounted. EV lines do NOT have machine mounted controls.

- Proven performance and durability in the toughest stamping applications

- Simple calibrating routine which provides extremely accurate work roll position control and repeatable set-ups

- User-friendly operator screens provide all information required for machine operation.

- Straightener set-up and operation is simple and easy to understand