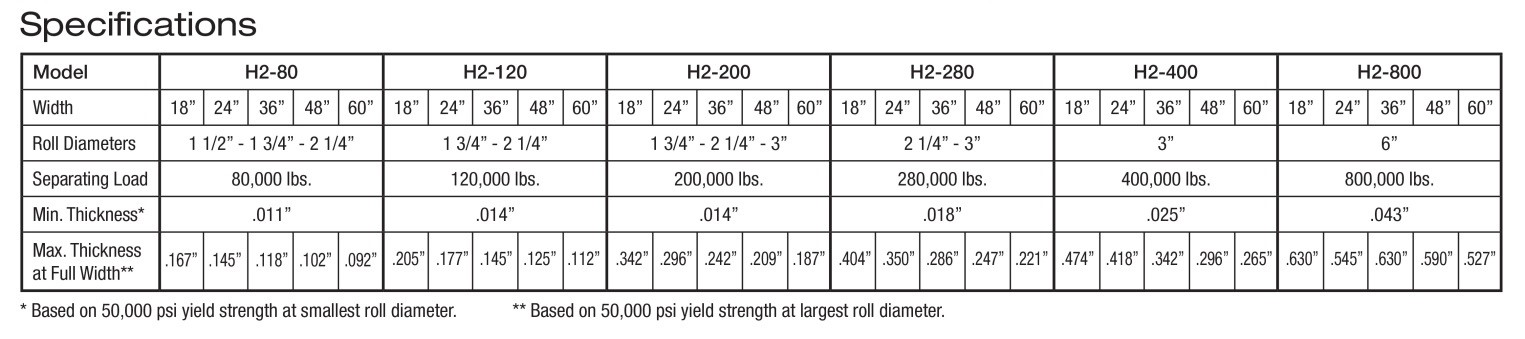

H2 and H2L family of straighteners have been designed for heavier gauges (.020” to .500”) and normally slower speed applications (30 to 200 FPM). Its ability to remove coil set and cross bow in today’s tough high-strength, low-alloy materials has proven itself in some of the most demanding applications.

The H2L series machines are built with a basic leveler cassette in the frame that is nearly the same as a precision straightener. The L series straighteners have all the same features as our standard precision straighteners in addition to incorporating manual roll bending.

Standard straighteners remove basic shape defects in a coil strip (such as coil set and cross bow) and can reduce the amount of edge wave and center buckle to some extent. However, for more severe coil defects and critical flatness applications, roll bending machines will remove much more edge wave and center buckle than a standard straightener.

Applications: High strength low alloy or advanced high strength steels (HSLA or AHSS) where typical flatteners cannot achieve the level of flatness.

Commonly Used Options

- Hammer Flattener – as the material enters the entry side of the straightener, the strip is likely to have coil set up or down, which can make it difficult to guide the material into the straightener. With a hydraulically actuated flattener bar, an operator can engage the bar to flatten the lead edge prior to entering the straightener, making it easier to thread the material through the cassette.

- Edge Guide – provides material guidance on the entry side of the straightener. A manually adjustable edge guide with protective covers can be easily installed or removed. (Option for motorized adjust).

- Thread Table – pivoting Bombay style or pivoting Roller style table that folds down while the line is running and pivots up to a horizontal position when an operator needs to thread material from the straightener to the feeder.

- Peeler Table – hydraulically actuated table that aids in threading material from a coil into the straightener in a safe and efficient manner.

- Hold Down Arm – hydraulically actuated arm that helps push the material along the peeler table into the straightener while maintaining pressure on the coil so it does not unwind on the decoiler.

Optional Features – Common to Series G2, G2 Plus, G2L, H2 & H2L Precision Straighteners

- Speed Control Package – provides stable, accurate loop control when straightener is feeding material into a loop

- Motorized Entry & Exit Adjustment – incorporates push button control of entry and exit roll position

- High Speed Option – provides an increase in speed to 4000 inches/minute, without loss of machine performance or capability

- Entry Edge Guide – provides material guidance on the entry side of the straightener

- Powered Pinch Roll – aids in threading of material into the straightener and extends the life of the work rolls

- Powered Pull Roll – polycoated roll with an independent motor located at the exit end of the straightener that adds tension to the strip to obtain more material in yield

- Chrome Work Rolls

- Hold Down Arm & Peeler Table – hydraulically actuated arm and table that aids in threading material from a coil into the straightener in a safe and efficient manner

- End of Strip Sensor

- Bolster Extension Kart with Arms – aids in the installation and removal of the cassette

- Single Arm Decoiler Controls – integrates Forward/Reverse, Mandrel Expand/Collapse, Hydraulic Pump Start/Stop controls on the main operator panel

- Double Arm Decoiler Controls

- Coil Car Controls

- Additional Auxiliary Decoiler Station Controls – integrated into a remote pedestal to assist in unloading a coil from the backside of the decoiler

- Automatic Tension Control – integrates controls to automatically adjust the pressure of the decoiler brake based on the diameter of the coil to maintain constant strip tension

- Press Interface Quick Disconnects

- Decoiler Interface Quick Disconnects

- Common Mounting Base – for assembling and mounting s-loop, straightener & decoiler