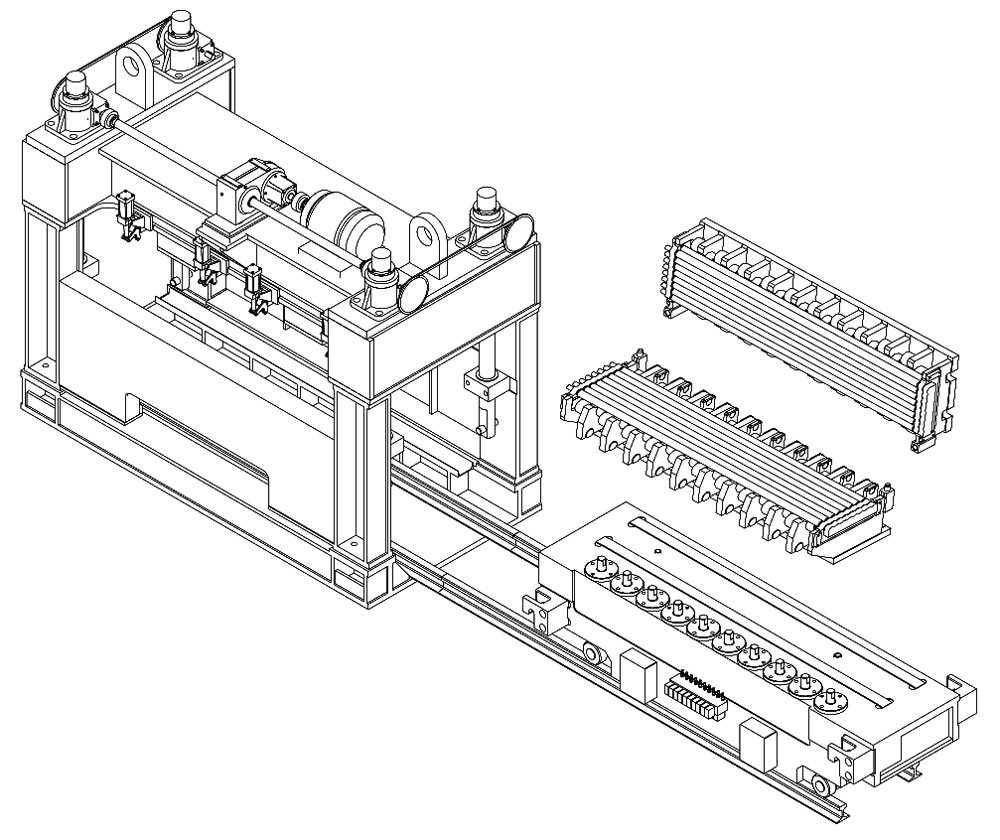

Removable Roll Cassettes

Levelers and straighteners in general are dirty machines; they don’t create dirt, they just collect it off the strip. Scale, oxide, dust, etc. gets deposited on the rolls and accumulates in the lower backup bearing area.

A removable roll cassette provides:

- Easy inspection

- Easy cleaning

- Easy maintenance

- Exchange with different roll diameters

Control Systems and Automation

- Hand cranks and pointers

- Motorized adjustments with position readouts

- Setup assistance based on material parameters and recipe storage

- Automation and closed loop shape control

Additional items and features you should evaluate

- Construction and roll support methods

- Types of roll bend methods exp: Wedge vs. Pivot

- Bearings and lubrication methods

- Types of position actuators, mechanical or hydraulic

- Variations of drive systems

- Strip handling options, tables, shears, side guides, threading rolls, etc.