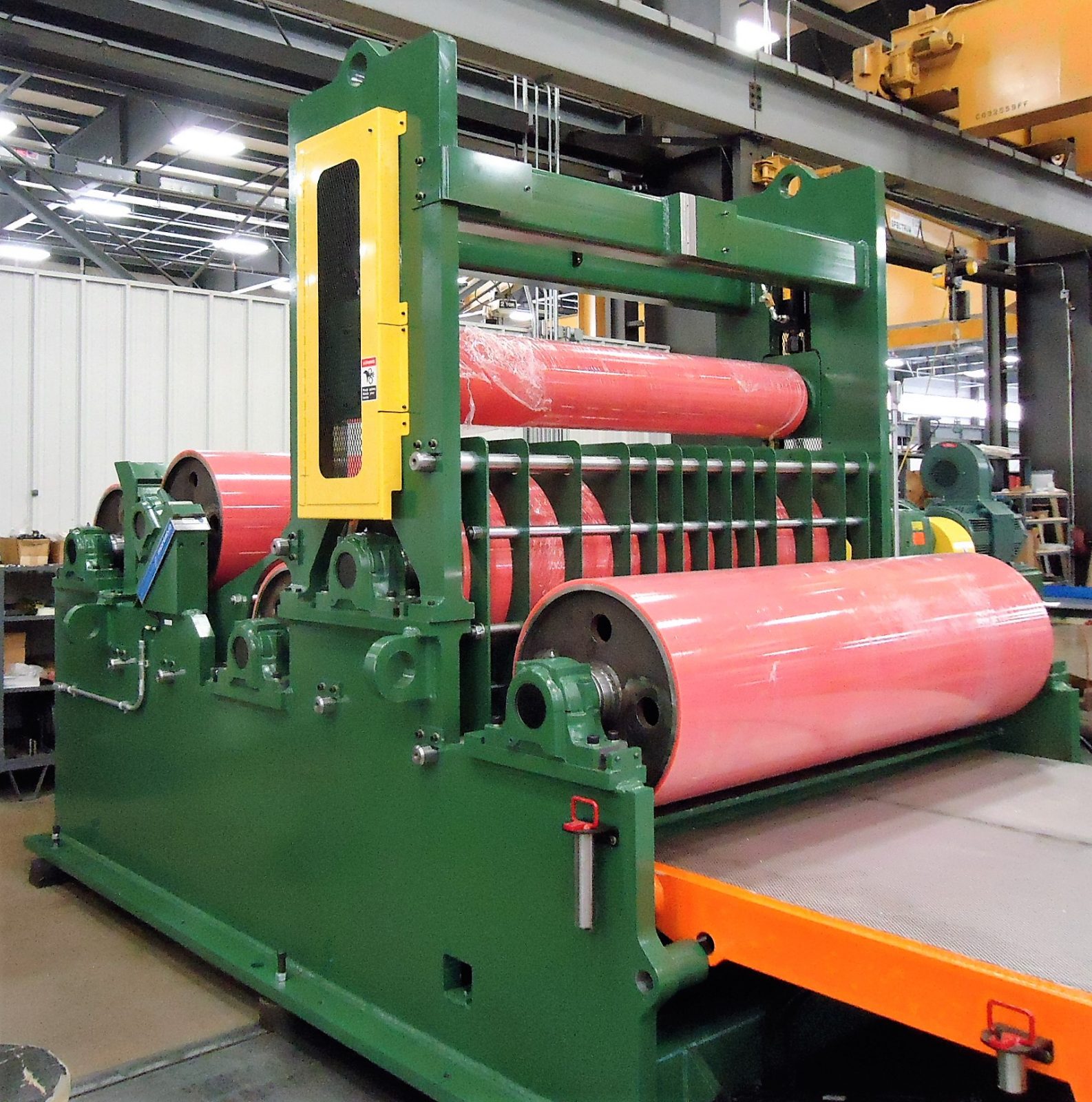

The setup of bridle rolls and the bridle roll stand is a vital component in a coil and continuous processing lines, as it facilitates the precise tension control of the metal strip as it passes through the various stages. By housing multiple driven rolls in an alternating over-and-under configuration, this setup allows for fine-tuned tension adjustments as the metal strip passes over one roll and then under the next.

At Machine Concepts, we engineer and manufacture bridle stands of multiple sizes and roll configurations for a wide range of coil processing applications, including tension leveling, cleaning, annealing, galvanizing and coating/painting. Bridle roll stands can be positioned at various locations in the line to manage the strip's tension entering and leaving each station or process tension zone.

The ability to precisely control tension is crucial in these processes to ensure consistent quality and prevent defects. Multiple options are available to customize the bridles' function and performance including snubber rolls, roll scrapers, threading guides and self-threading options. Custom drive configurations are also available to save space or to work around existing equipment.

At Machine Concepts, custom-designed bridle stands for new applications or for retrofitting into existing lines is one of our specialties.

Entry Bridle Roll Stand

Entry bridle roll with threading table and exit load cell roll. This set-up allows the operator to quickly thread the material as well as give accurate tension read-outs to the operator.